Machinery Investments Continue at Faulkner Moulds

Faulkner Moulds has recently taken delivery of a new Hurco TM8i 2-axis CNC turning centre and Mitutoyo Crysta-Apex S coordinate measuring machine; both welcome additions to the Yorkshire-based toolmaker’s ever-growing suite of state-of-the-art machinery.

Three times UK ‘Toolmaker of the Year‘, Faulkner Moulds continually invests in machinery and training to stay ahead of the game and improve services for its customers.

The latest addition to the Faulkner toolroom is a Mitutoyo Crysta-Apex S coordinate measuring machine (CMM), purchased due to the increased demand for tighter tolerances in toolmaking, allowing highly accurate 3D measurements at high speed. Dedicated software algorithms guarantee the highest accuracy by eliminating even minuscule geometrical imperfections in the guideways.

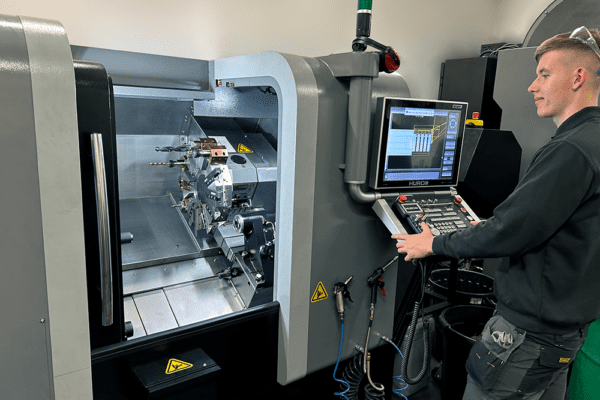

Further to the new CMM, Faulkner also recently took delivery of a new CNC turning centre from Hurco. The versatile turning centre has in-built features to ease programming, enhance machine speed and ensure outstanding accuracy and surface finish. Thus, it is ideally suited to the fast-paced demands of milling, drilling, tapping and turning in modern toolmaking. Faulkner Moulds’ recent experience in high precision turning includes projects for the medical, packaging and industrial sectors.

Other recent investments include a new wire erosion machine and a new CNC sparker that runs to a guaranteed 3 microns accuracy all day.

The two newest machines are already in daily use, helping Faulkner Moulds respond to increased demand for both high precision circular toolmaking and extreme measurement accuracy.

With more machinery investments at Faulkner Moulds in the pipeline, watch this space!

Faulkner Moulds

01422 371072

Website

Email