LATI Launch New Thermoplastic Compounds for Future Automotive Applications

For some time now, the automotive sector has been involved in an ongoing change of enormous significance linked to the introduction of hybrid and electric mobility projects designed gradually to phase out traditional combustion engines in cars.

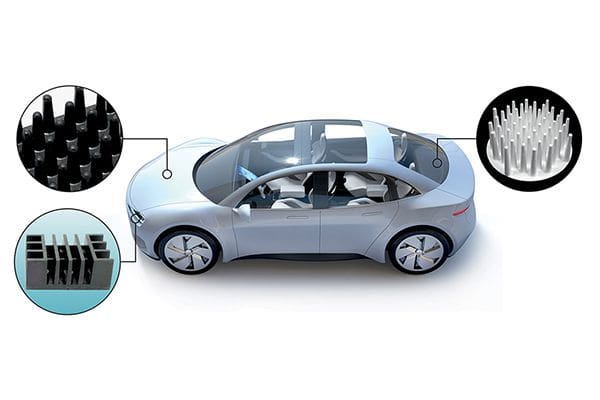

The cars of the future are also destined to see the introduction of other important innovations, first and foremost the extreme integration of electronic systems for self-driving and connectivity applications. In this scenario, synthetic materials of all kinds, ranging from composites to aluminium alloys, ceramics and special thermoplastic compounds, are set to find an ever-increasing range of applications.

A fundamental goal for designers is to obtain lightweight structures. Although this is easily achieved thanks to the use of plastic materials, it comes at the expense of important features such as cooling capacity and strength, typical of metals.

Today, however, mechanical strength and thermal conductivity are combined in LATICONTHER MI, a new family of LATI thermoplastic compounds specially designed for the automotive applications of the future.

The basic objective of the MI grades is to increase as much as possible the thermal performance of the material without foregoing the mechanical features typical of glass fibre-reinforced compounds. This challenge is made even more complex by the need to deliver solutions that are chemically and thermally suitable for the typical application conditions of the modern automotive industry.

The LATICONTHER MI compounds are based on 35% glass fibre-reinforced PA66, a formula widely used and much appreciated within engineering and design fields. The thermoplastic matrix is stabilized to withstand chemical attack by the fluids typically found in the engine compartment, namely lubricants, fuels and coolants.

Higher thermal conductivity performance is achieved by filling the basic composition with special additives designed to facilitate heat transfer without, however, affecting the mechanical strength of the material. The result is a compound with a tensile strength far above 100 MPa and a thermal conductivity over ten times higher than that of traditional solutions.

The MI01 grade focuses on mechanical performance, with a tensile strength of nearly 150 MPa associated with a thermal conductivity of 2 W/mK, as opposed to the 0.2-0.3 W/mK of other conventional 35% glass fibre-reinforced PA66 compounds.

Instead, the MI02 solution offers heat transfer capacity, providing thermal conductivity of about 5 W/mK lengthwise and greater than 1 W/mK crosswise. These values are extremely high when considering the tensile strength (120 MPa) and elastic modulus (15 GPa) achieved by this compound.

The LATICONTHER MI01 and MI02 compounds can meet designers’ requirements not only in the automotive sector, but also in other application fields requiring faster heat dissipation through structural components, as well as improved strength and reliability of cooling elements. All this while still ensuring a lighter weight, given that the density of both materials remains well below 1.6 g/cu.cm.

Other solutions based on PP, PBT and PPS are now in the development stage in the LATI laboratories.

LATI UK

+44 (0) 1270 501713

Website

Email