LATI Develop PTFE-free Self-lubricating Compounds

PTFE is a polymer with peculiar characteristics, including a very low friction coefficient. This property can be transferred onto different thermoplastic matrices by dispersing appropriate percentages of PTFE into them though compounding.

The tribological behaviour of such formulas stands out for low static and dynamic friction coefficients, even for grades reinforced with glass or carbon fibre.

The elevated performance delivered by the PTFE enables the use of these self-lubricating compounds in technologically advanced applications where wear and friction need to be limited.

The processing of self-lubricating compounds containing PTFE however has a disadvantage linked to the formation of deposits on moulds, and corrosion problems for equipment and the danger of fumes due to the possible thermal deterioration of part of the PTFE. Formulas containing PTFE also have problems caused by fluorine, a halogen whose presence is today subject to increasingly stringent regulatory restrictions due to the risks associated with their release into the environment at the end of their life.

The replacement of PTFE is therefore a highly topical debate and LATI (www.lati.com) has developed a family of self-lubricating grades, Latilub, formulated to ensure high tribological performance without the use of fluoropolymers. Lati chose UHMWPE as a replacement polymer, an ultra-high-molecular-weight polyolefin known for its extreme resistance to abrasion.

The results are encouraging, even in formulas highly reinforced with glass fibre. The UHMWPE, dispersed in amorphous or semi-crystalline matrices, means friction coefficients are comparable to PTFE with similar run-in times.

Even abrasive and adhesive wear has been clearly slowed. From a mechanical standpoint, no significant differences were noted under static load action nor in the presence of impulsive stresses. Lastly, the lower density compared to PTFE permits solutions that are interesting also from an economic point of view.

UHMWPE Latilub are available in reinforced and non-reinforced grades, also with additional self-lubricating systems (for example, silicon oil or aramid fibres) and for thermal performance up to 200 °C. LATI supports Latilub formulas also by facilitating the work of engineers and designers.

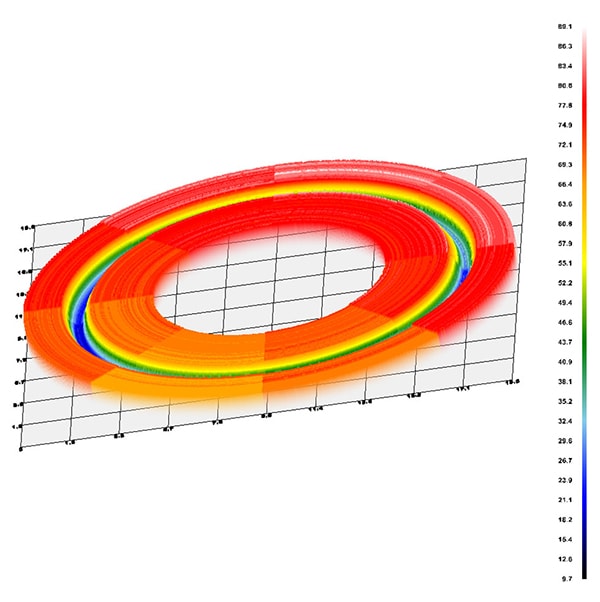

Latilub 66-10E G/15 with UHMWPE has obtained Gold Moldflow characterization, enabling the simulation of moulding with the utmost reliability.

LATI UK

+44 (0) 1270 501713

Website

Email