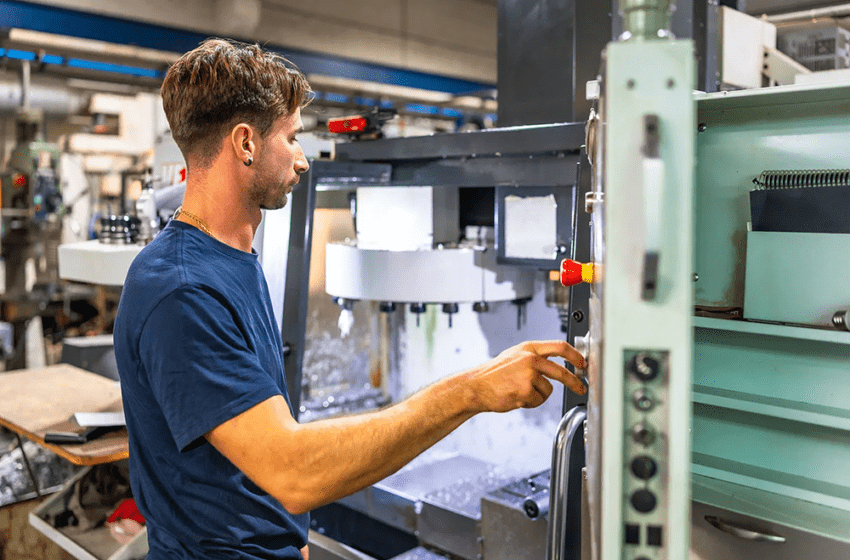

In manufacturing, the term “downtime” often carries negative connotations, as any inactivity can result in lost revenue. However, downtime can occur for various reasons, some planned and necessary, others unplanned and costly. In this article, FourJaw explores how manufacturers can minimise unplanned downtime by optimising processes, leveraging technology, and empowering their workforce.

Return on investment, or ROI is a key performance indicator (KPI) that’s used by businesses to determine the likely Read More

Choosing the right 3D scanner for your business can be daunting, especially with the vast array of options available on Read More

Energy consumption is one of the biggest expenses for factories that significantly impacts both finances and the environment. A company Read More

Intouch Monitoring Blog // Six Strategies to Boost Manufacturing Efficiency Without Major Investment

Manufacturing efficiency is key to staying competitive, and small, strategic improvements can drive significant gains. Intouch Monitoring’s Manufacturing Execution Read More

You likely appreciate the benefits of ISO management systems—efficiency, compliance, and credibility. You might even believe in the principles Read More

Every successful manufacturing business, much like your favourite cocktail or the way you like your toast, needs the right blend Read More

When choosing solar panels for your business, there are a number of decisions to make and options to consider, including Read More

Plastic manufacturers are constantly seeking ways to streamline production, reduce costs, and ensure exceptional product quality. For businesses considering plastic Read More

Plastic regrind is derived from processing scrap or waste plastic into small, uniform particles. This process enhances resource efficiency and Read More