KUKA and AMTCE Help to Bridge Skills Gap in Ireland

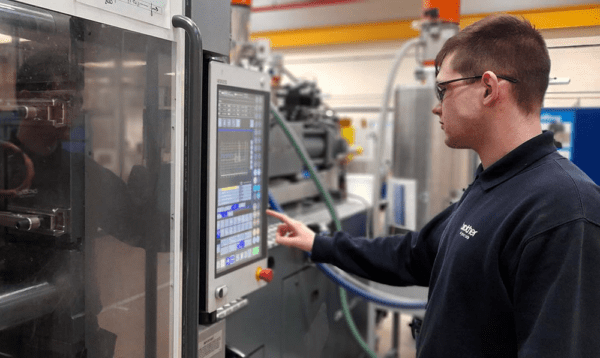

Working with KUKA Robotics Ireland, the Advanced Manufacturing Technology Centre of Excellence (AMTCE) will provide opportunities for companies and employees to upskill in automation technologies relevant to the industry using state-of-the-art equipment and processes.

The Advanced Manufacturing Technology Centre of Excellence (AMTCE) was established in 2020 to address the skills and training needs of the Irish manufacturing sector. Located in the Xerox Technology Park, Dundalk, its ambition is to become the leading provider of advanced manufacturing training in Ireland.

The AMTCE will help to bridge the skills gap by providing opportunities for companies and their employees to upskill or rescale in technologies that are relevant to industry by way of practically orientated ‘hands-on experience’ training with state-of-the-art equipment, delivered by leading industry trainers using flexible delivery modes in response to changing industry needs.

The industry will benefit massively from the centre once it is fully up and running by coming into the centre and getting hands-on exposure to the latest in advanced manufacturing technologies, including robotics, cobotics and other robotic processes such as welding and 3D printing. They can then operationalise those technologies within their businesses to drive increased productivity, competitiveness, and operational resilience.

Michael McGrath, Director at AMTCE, said of the centre’s development: “The hope with Industry 4.0 and related technologies is that countries like Ireland can compete on the global stage, based on innovation rather than low cost. The centre really is about putting that sort of intellectual capacity, skills, and capability into the Irish industry so that it can compete.”

The KUKA group has always had a large focus on research and education. Since establishing KUKA Ireland back in 2014, it has concentrated on the research centre and the developing education sector here in Ireland.

Brian Cooney, Managing Director of KUKA Ireland, said: “What’s very different about us from an Irish context is that KUKA is actually the only robot manufacturer that has sales, service, application engineering, and training, all within a dedicated facility here in Ireland.

“We’re quite unique in that regard, and it gives us a strong basis with which to work with all our research partners, rather than the resource being provided from outside Ireland.”

The Advanced Manufacturing Technology Centre of Excellence

The AMTCE represents a significant public investment in the training needs of the Irish manufacturing sector. The centre is dedicated to providing high-quality training through various delivery modes in Industry 4.0 using state-of-the-art technologies for delivery and learning.

AMTCE said: “A skilled workforce which evolves in response to technology advancement and opportunity is critical to the sustainable success of companies as they navigate through the digital transformation of their companies.”

The AMTCE provides an opportunity to revolutionise traditional crafts and hands-on skills and combine legacy technologies with the latest in innovations, such as robotics, putting the next generation of technology capabilities in place, and to then train people on those technologies, such as robotic welding, the likes of which will really shape how manufacturers will operate into the future.

Michael added: “This centre is located in the largest population centre in Ireland, outside of Dublin. There are over two and a half million people within one hour of the centre’s location and seven universities. It’s really about partnership, and that’s one of the key reasons why we work with the likes of KUKA because they provide state-of-the-art equipment, but they’re also a partner who we shall work with to develop training because we’re very much about the development of skills delivery and training. We, therefore, required a partnership with our vendors in order to realise that goal.”

The way that technology is starting to evolve and certainly the new types and kinds of processes that are emerging is interesting. It’s about fusing technologies into new technology platforms. Robotic processes are no longer just a manual movement of material from A to B to C; it’s now about combining robotics with technology such as welding, 3D printing, visual inspection systems or other forms of inspection capability. Legacy technology is being combined with the latest in robotics to deliver the next generation of technologies, catalysing the innovation and onward development of the industry.

Brian said of the evolution of research and development initiatives in Ireland: “It’s changed over the last number of years. There has been a lot of funding put into research and development initiatives by the government and through EU funding.

“A lot of research programs are being established, but the AMTCE is quite unique in that it’s actually looking at research from the point of view of lower levels; so level six, taking individuals who have a certain level of education within manufacturing but enabling them to upskill and reskill in cutting-edge technologies and state-of-the-art manufacturing principles. In that respect, it’s unique within Europe.”

Michael summarised: “We are investing quite heavily in a lot of e-learning technologies which will allow us to have both a national reach, but also to extend beyond our borders into Europe, so we’ll be looking to the future for our further opportunities in order to extend our reach outside Ireland. Leading industry practitioners will provide our training and that allows us to be agile and to be nimble, and to respond to the needs of the manufacturing industry in very quick order.”

![]()

KUKA Robotics UK Ltd

+44 121 505 9970

Website

Email