KraussMaffei Bundles all Extrusion Technologies Under One Roof

The KraussMaffei Group has bundled its technological know-how and decades of experience in extrusion by merging its corporate extrusion operations at a single location.

This strategic approach results in substantial product benefits for customers, valuable synergy effects for the company and new opportunities and fields of research for the future. The highlight will be the world’s most modern extrusion R&D centre currently built at the company’s new site in Laatzen on the outskirts of Hannover. The new plant is part of the largest investment program in KraussMaffei’s history. The relocation of the entire extrusion division is scheduled for the second half of 2022.

Dr. Volker Nilles, Executive Vice President for New Machinery Business at KraussMaffei, said:

“Against the background of KraussMaffei’s growth plans, bundling the extrusion activities at one location is the right strategic response to current and future challenges in our industry.

“With our Hannover-based technology centre for the most diverse extrusion applications, and especially with our move to the new site in 2022, we are taking our expertise to a new level.”

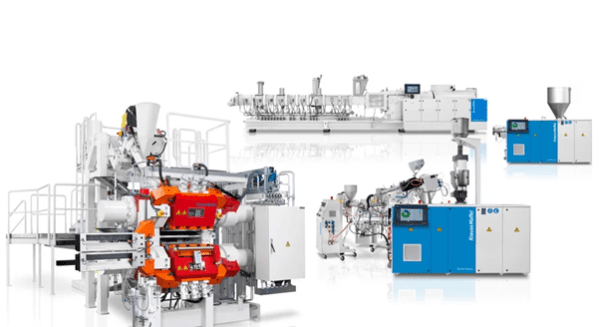

The product portfolio offered by the KraussMaffei Group covers almost all extrusion technologies and has done so for over 20 years – from the extrusion of pipes and profiles to sheet and flat film, rubber and foam extrusion up to compounding and recycling. All these different technologies will be brought together at a single location.

Customer benefits, synergies and strategic outlook for the future

Well before the current discussions on resource conservation and processing of recycled material, direct processing concepts were increasingly coming into focus. Material processing in a “single heat” generally reduces the thermal stress the material is exposed to and requires fewer process steps and less energy. The production of wastewater pipes from highly mineral-filled compounds is a typical example of a direct processing concept in pipe extrusion. The PP barium sulphate compound is prepared on a co-rotating twin-screw extruder and shaped by the downstream pipe extrusion head in a single process.

Volker added:

“Beyond our direct processing solutions that have already been tried and tested, the R&D centre now offers our experts the opportunity to implement and test completely new ideas.”

The enormous wealth of experience gathered at KraussMaffei’s Munich and Hannover sites in the past will now be bundled, which offers unique opportunities to launch new research and development projects geared towards new materials as well as new final products.

The new R&D centre will offer ideal conditions for all extrusion companies opting to produce their own starting materials (also from reclaimed material) or processors wishing to add new end products to their current product portfolios.

Volker said:

“Customers will get a live experience of all the technologies available at KraussMaffei and they will be able to carry out trials with their own raw materials and talk to experienced staff from all extrusion areas like compounding, pipe and profile extrusion as well as with our specialists in digitalisation and Industry 4.0. This saves time and substantially simplifies coordination.”

New sales and organisational structure

Despite all the changes involved in the integration of the individual divisions, KraussMaffei is committed above all to continuing the trusting cooperation with customers and suppliers. In order to ensure even more efficient customer advice and support around the globe in the future, the sales team has been completely reorganised.

Volker explained:

“Thanks to the new KraussMaffei sales structure based on closer cooperation between technical experts and regional sales, we will be able to intensify our customer support capacities.”

The new structure involves all extrusion divisions. At the same time, the pipe and profile expert team will be strengthened by new colleagues.

He added:

“We are firmly convinced that we are well prepared for future challenges in the extrusion industry, no matter what the application.”

In addition, KraussMaffei is bundling its service capacities in the field of Digital Service & Solutions (DSS), which further enhances the customer service offering.

Unique extrusion R&D centre in the new plant

From the third quarter of 2022, the wide range of technological solutions included in KraussMaffei’s extrusion portfolio will be available to customers at a single location. The large extrusion R&D centre is the highlight of the new plant currently built on the outskirts of Hannover, where all extrusion divisions from Munich and Hannover with up to 700 employees will be brought together. On a floor area of 10,000 square meters, 26 extrusion lines can be used for trials. What’s new is that these lines will be installed in production scale – i.e., over the full length, including the entire downstream equipment, e.g., cooling section, take-off system, winder and separating system.

KraussMaffei

+44 (0) 1925 644100

Website

Email