KraussMaffei Extrusion Technology Plays Powerful Part in Panel Production

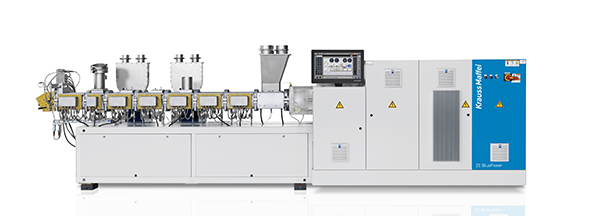

In a recent project funded by the German Federal Ministry for Economic Affairs and Energy (BMWi), KraussMaffei and several other partners produced cross-linked foam boards on a ZE BluePower extruder.

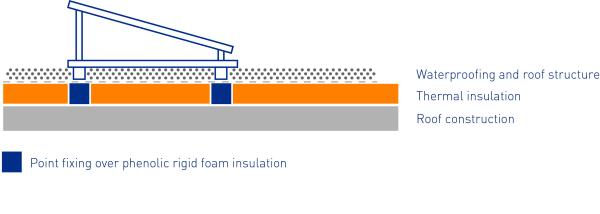

In its capacity as one of six associated partners, KraussMaffei has promoted a cooperation project funded by the BMWi. The common aim of the project partners was to develop a closed value-added chain for thermoset rigid phenolic foam – starting from the production, through planning, construction and operation up to material recycling. The highly innovative rigid foam products are ideal for use as load-bearing insulating composite components in the building sector, e.g., for mounting solar modules or air conditioning systems on roofs or for the installation of windows, railings, or awnings to the building façade.

KraussMaffei promotes research project

Within the frame of this project, KraussMaffei’s extrusion division succeeded in matching the phenolic compound formulation and the process control in order to be able to extrude boards with low density, high mechanical stability, low thermal conductivity and good fire resistance on a co-rotating twin-screw extruder. “The excellent fire properties of the new thermoset foam boards are indeed something very special,” declares Andreas Madle, Process Engineer in the Process-Engineering Development Division and Project Manager at KraussMaffei. Even without the addition of flame retardants, the new material is extremely flame resistant and hence classified as fire protection class B1.

Optimally configured twin-screw extruder keeps cross-linkage under control

The ZE 42 BluePower twin-screw extruder available in KraussMaffei’s R&D centre in Hannover was used to produce foam boards with a thickness of 50mm. In terms of process-engineering characteristics, this extruder was precisely adapted to the requirements of the material processed. “The challenge was to keep the cross-linking process in the extruder under control and to avoid the formation of dead spots,” says Andreas Madle. This goal has been achieved through a low-shear screw geometry, moderate processing temperatures ranging between 100 and 120°C, and the selection of a screw tip that is characterised by an extremely reduced free volume.

The final product is a thermoset foam with a density of about 800 kg/m3 and good thermal conductivity of 0.12 W/mK. “We are well aware of the fact that our foam is rather heavy compared to thermoplastic foam such as EPS, which can reach densities of less than 30 kg/m3,” states Andreas Madle. “However, these two foam products are not really comparable as their fields of application are completely different. In fact, the new foam is intended, among others, as an insulating material for loaded applications and the higher mechanical stability involved inevitably requires a higher density.” Furthermore, the process engineer is convinced that future research and development projects will allow the density of phenolic resin foam to be further reduced.

The other cooperation partners involved in this project were Hexion GmbH (phenolic resins), Ejot Baubefestigungen GmbH (fastening solutions for the building industry), Schöck Bauteile GmbH (load-bearing insulating components) as well as Robert Bosch GmbH (various products and consumer goods). The project has been coordinated by Chemnitz Technical University, Faculty of Mechanical Engineering, Chair in Plastics.

KraussMaffei

+44 (0) 1925 644100

Website

Email