KraussMaffei at Compounding World Expo Europe

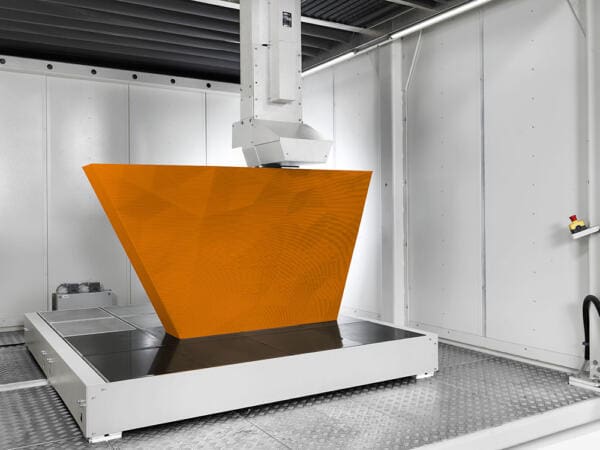

At the upcoming Compounding World Expo Europe, held in Essen, Germany, from 14 to 15 June 2023, KraussMaffei will offer its visitors a real attention-grabber at booth A433: a unique bar height table printed with the pellet-based powerPrint large-format 3D printer.

The highlight of the solution exhibited at the trade show is not the table itself, but the raw materials based on recycled plastics it is made from, and the fact that the machinery involved in the process – from the compounding line with ZE BluePower twin-screw extruder to the additive manufacturing solution and the film and sheet extrusion line for the table top – can be provided from a single source.

High-grade raw materials are key to delivering premium-quality finished products in plastics processing applications. The process adopted in manufacturing compounds is particularly important if the input material is based on recycled plastics. Compounding lines for producing high-quality compounds based on recycled materials are one of KraussMaffei’s chief specialities.

In particular, the well-established ZE BluePower twin-screw extruder – with its ideal ratio between screw volume and screw torque – provides optimum melt homogenisation and perfect incorporation of additives. As required in this case, glass fibres. And, to complete the processing section of the ZE BluePower extruder, there are appropriate metering systems for solid and (if used) liquid additives, as well as vent ports through which moisture, volatile components and odour build-up can escape when processing recycled materials.

With KrausMaffei’s in-depth mechanical engineering expertise and extensive knowledge of formulations, the compounds required for additive manufacturing can be produced to ideal quality specifications based on different material types and different proportions of recycled materials with glass fibre or carbon fibre reinforcement and the appropriate colour masterbatch.

Sustainable and efficient component manufacturing

The pellet-based powerPrint large-format 3D printer, which debuted on the market at K 2022, has several special features for industrial components manufacturing. Direct processing of the pellets made in the compounding line eliminates the need for filament production, which enhances process flexibility and results in a more cost-effective and sustainable process. Furthermore, the powerPrint enables the printing of large-format components with build volumes of up to 2 m x 2.5 m x 2 m. The closed, thermally insulated enclosure makes for reliable printing (with excellent process stability) of, for example, casting moulds for tool and mould making, autoclave components or pipe ducts and conduits. This means the large-format 3D printer is a fast, dependable industrial solution for efficient production of near-net-shape components.

As an extrusion-based system, the powerPrint enables direct processing of pellets while offering outstanding flexibility in terms of the raw materials that can be used at temperatures up to 400°C. Owing to KraussMaffei’s wealth of expertise in extruder engineering, the processing unit boasts superior wear resistance at high production speeds. Customized designs can be provided whenever requested. The table demonstrated at the Expo, printed with the powerPrint 3D printer, impressively showcases the scope for manufacturing large components based on compounds from recycled materials.

Table tops made from recycled materials

A table also needs a base, which comes from the 3D printer, as well as a top. As with the base, the table top can also be made from recycled materials. KraussMaffei offers the right processing machine for this application. The unique feature of the tabletop, which will be shown at the Expo, is that it’s actually a 5 mm thick floor covering manufactured on an in-line compounding and laminating line. It is a mono-material solution that can be easily recycled again; while the laminated decorative film is made of pure PP, the core sheet of the table top consists of PP with a chalk content as high as 80%.

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email