KraussMaffei Offers Free Trial of Revolutionary APCplus ‘Cruise Control’ Process Control Software

|

Getting your Trinity Audio player ready...

|

KraussMaffei, a global leader in machinery and solutions for plastics and rubber processing, has announced a complimentary trial of its industry-leading APCplus (Adaptive Process Control) software. This trial is available with every new KraussMaffei injection moulding machine, enabling injection moulders to experience firsthand the precision, efficiency, and sustainability benefits of APCplus.

APCplus from KraussMaffei uses Adaptive Process Control to automatically monitor and adjust key parameters in real time, ensuring consistent shot quality across every injection moulding cycle. This patented technology compensates for variations in temperature, humidity, material consistency, and other external factors, which typically disrupt the stability of the injection moulding process. Just as cruise control in a vehicle keeps a constant speed on varied terrain, APCplus regulates the injection moulding process, resulting in optimal shot weight and component quality—cycle after cycle.

“APCplus is a transformative tool that gives manufacturers the confidence of stable, high-quality production across every cycle,” said Michael Rudd, Aftersales Director at KraussMaffei Group UK. “With this trial, customers can experience firsthand how APCplus stabilises production, reduces waste, and improves sustainability, and we’re delighted to be able to offer this to injection moulders.”

APCplus at a Glance: Minimise External Influence, Maximise Productivity

- Automatically adjust to account for external influences shot after shot

- Achieve consistently high quality with intelligent production control

- Significant increase in good parts due to improved process stability

- Detailed process information automatically recorded every shot

- Easy adoption of recycled materials with high process consistency

- Reduced lifecycle costs due to less material consumption and waste

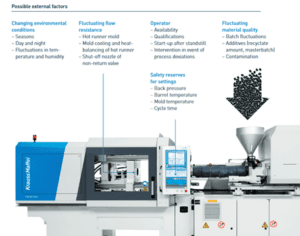

Which External Factors Influence My Process?

Every fluctuation in external factors can directly lead to changes in fluid viscosity between cycles, leading to a change in polymer behaviour in the mould.

With fixed process parameters, these fluctuations are not accounted for and could result in defects and inconsistencies in the final components.

Adjusting in Real-Time

APCplus analyses and continually compares the current process state with the configured reference curve.

The change-over point and the holding pressure profile are automatically adjusted for every single shot, with no operator intervention required.

With all external fluctuations cancelled out in real-time, the mould fills completely and consistently, providing higher quality parts and a vast reduction in reject rate.

Consistency in Recycled Materials

APCplus also shines when it comes to inconsistent materials – a common feature of recycled polymer grades. Regardless of the proportion and properties of your recycled materials, APCplus continues to react to fluctuations and reliably stabilises component weight. (See below image). With APCplus you can easily master sophisticated processes even when using high proportions of recycled materials.

Consistency in Recycled Materials

APCplus also shines when it comes to inconsistent materials – a common feature of recycled polymer grades. Regardless of the proportion and properties of your recycled materials, APCplus continues to react to fluctuations and reliably stabilises component weight. (See below image). With APCplus you can easily master sophisticated processes even when using high proportions of recycled materials.

This example represents 26 days of production to manufacture 20,000 products, for a total saving of £1826, or a £70.23 saving every day. For a typical 48-week, 5-day week manufacturer, this represents an annual saving potential of £16,855, without factoring in additional savings such as purging, training and more.

Calculate Your Own APCplus Advantage

APCplus technology from KraussMaffei enables significant reductions in your manufacturing costs, and we invite you to test the potential savings yourself using your personal production parameters.

These calculations are made simple with KraussMaffei’s digital APCplus calculator, available to use for free by clicking here.

For more information about APCplus and to start your free trial, reach out to the KraussMaffei UK team today and discover how APCplus will revolutionise your injection moulding production processes.

Read more news from KraussMaffei here.

KraussMaffei

+44 (0) 1925 644100

Website

Email