KLEENOIL UK Issues Warning about Varnish Contamination

Varnish has emerged as one of the deadliest of oil contaminants in industry, says KLEENOIL UK, specialist oil filtration provider.

Just like heat, particle and moisture contamination, varnish acts as a soft contaminant that severely impacts lubrication and machine reliability. Injection moulders are highly susceptible to varnishing as the high isolated heat areas are a major contributing factor to its creation. While there is no way of totally removing the scale and gum, it can be prevented or minimised with constant micron filtration.

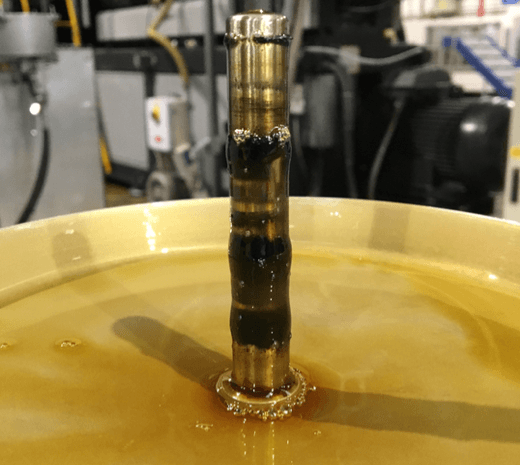

The working oil in an injection moulding machine will inevitably become contaminated if it is not cared for properly. Users may notice a brown, gummy varnish build upon various moving parts of the machine. This is the result of insoluble contaminants forming in the hydraulic oil, leading to plugged hydraulic filters, injection valve sticking, and reduction in flow rate.

Signs of contaminated hydraulic fluid include:

• Erratic injection

• Flash or short shots

• Variable pressure

• Sticking valves

• Filter plugging

• Increased filter changes

• Build-up of varnish on oil-wetted surfaces

A major issue is that varnish particles are known to be smaller than the size ratings of most filters, meaning they cannot be removed using conventional pore-size related filtration.

KLEENOIL is a traditional cellulose depth filtration method, and one of its attributes is its ability to apply absorption. Adsorption is the adhesion of molecules to a solid surface. KLEENOIL, as a high-quality oil filter, utilises cellulose and its high surface area, so due to its chemical nature, the fibres are highly suited to pick up oxygenated organic molecules such as varnish. This minimises its creation, making it a very effective, affordable filtration method to tackle this rising problem.

KLEENOIL also offers the addition of a 4000 gauss magnetic core to the filtration system. This allows passing oil to adhere to all ferrous and ferric material, further entrapping submicron material that will further contribute to the varnishing.

KLEENOIL UK

01977 682810

Website

Email