Intouch Monitoring: Increased Visibility, Improved Performance, Increased Profits

In a manufacturing environment where customers expect more for less, it is vital to drive costs out of your processes. Intouch real-time scheduling, monitoring and reporting system gives you the visibility and control to easily make continuous improvement decisions; allowing you to improve OEE and increase productivity whilst maintaining or reducing time, machines, labour and energy.

Intouch’s flexible and affordable systems are designed to be understandable and easy to use, and come with an exceptional level of customer support.

Monitoring

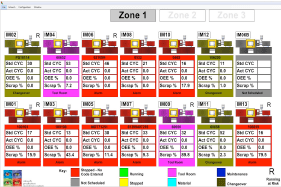

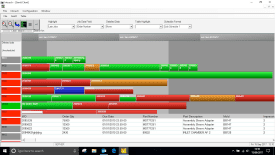

Key performance figures such as output speeds, run time, down-time, good/scrap production and utilisation are graphically displayed on fully configurable and tailored diagrams which can be seen at a glance.

High visibility of shop floor status motivates production staff to be seen to be ‘doing a good job’ encouraging them to keep machines operational.

Scheduling

Rescheduling is easily achieved through a simple drag and drop operation which can be forward or backwards scheduled to highlight spare capacity.

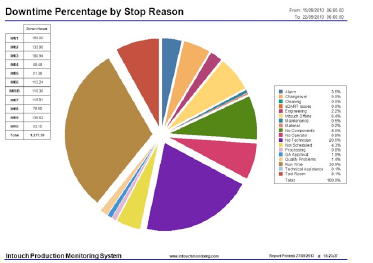

Reporting

All data collected by Intouch is automatically and accurately recorded in the archive database and made available to the Intouch reporting module. The data enables informed decisions to be made to streamline production operations and monitor key processes to better control final product quality to achieve a “zero defect” policy. Reports can be configured for any selected time-period and available by machine, tool, product, workgroup or operator with many key performance figures such as OEE, scrap, down time or any other custom defined parameters.

Founded in 1997 by a production manager and an engineer, Intouch systems are installed in over 200 sites worldwide across a multitude of industries from automotive and packaging to aerospace and medical.

Intouch systems work with many different processes including injection moulding, assembly operations, CNC cutting/machining, extrusion, metal-stamping, printing, thermo-forming, food processing and many more.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email