Intelicare Installation at University of Edinburgh Furthers Research and Education

The University of Edinburgh’s School of Engineering recently contracted Intelicare to install a P.E.I Pinette heated platen press and a Frigosystem chiller, for use in research and teaching in the field of thermoplastic composites.

The University of Edinburgh, founded in 1582, the eighth-largest university in the United Kingdom and an internationally renowned centre of academic excellence, has installed a P.E.I. Pinette heated platen press and a Frigosystem chiller in its Processing Laboratory in the School of Engineering.

The equipment has been added to the Institute for Materials and Processes as part of equipment run by Professor Conchúr Ó Brádaigh and is to be used in research and teaching where individuals wish to manufacture composite laminates or polymer plaques by compression moulding techniques. In particular, high-temperature thermoplastic composites such as polyether ether ketone/carbon fibre (PEEK/CF) or polyaryl ether ketone/CF (PAEK/CF) composites will be developed and manufactured.

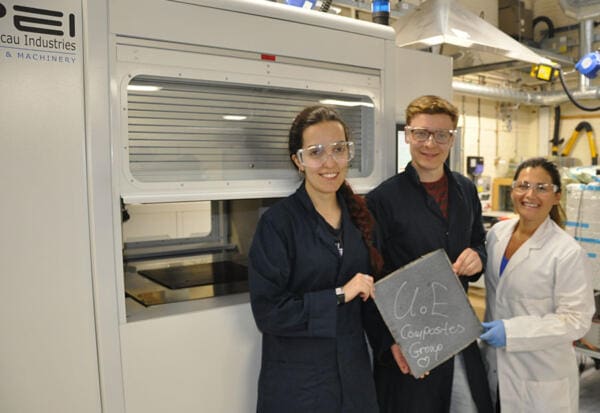

The first composite sample produced on the press is proudly displayed by Helena Pérez Martin, Sean Martin-Beattie and Eva Pappa from the University of Edinburgh, pictured above.

The platen press is a P.E.I. Pinette model LAB 450 P with 400mm x 400mm platens, a press force up to 30 tonnes, electric top and bottom platen heating up to 450℃ with an integral touch screen incorporating state of the art control of all press functions including recipe building, storage, download and internet connection for remote operation/diagnostics.

Rapid and controlled platen cooling is accomplished by the Frigosystem air-cooled NRA12 – M306 Chiller, which chills the water in a closed circuit connected with the platen press. This range of Frigosystem chillers has been specially adapted to operate with heated platen presses where very hot water, steam and hot compressed air exit from the platens and enter the chiller.

Intelicare undertook the installation and commissioning of the press and chiller, with P.E.I. completing the training of the Composites Processing Laboratory staff in October 2019.

The press has been well received as demonstrated by Dr. Dipa Roy, Senior Lecturer in Composite Materials and Processing, who commented: “The Composites Group at the University of Edinburgh is very active in advanced thermoplastic composites research. We expect this technically advanced press, together with the high capacity chiller for controlled cooling, essential for developing the desired level of crystallinity in the material during thermoplastic processing, to not only enhance the high-temperature thermoplastic composite research activity but to play a major role in the development of our students. The students from the Composites Group have produced the first advanced thermoplastic composite samples on the press, and the results are very impressive.” (Pictured, featured image)

Phil Jones, Intelicare’s technical manager, said: “Intelicare has evolved over the last few years, being involved in much larger turn-key projects, rather than simply the supply of individual equipment (which we obviously still can do, though!). This applies to all our partners, for presses, complete cooling systems, and extrusion projects. I’m really proud of the team we’ve put together here at Intelicare, who have lots of experience covering a whole range of projects. The Edinburgh press was a competitive process, but the equipment we provided and the value we were able to add ultimately helped us shine through.”

Intelicare specialises in the supply and service of equipment used within the plastics processing and composites industries, from single units to complete projects. Key product lines include industrial chillers and temperature control, complete extrusion lines, materials handling, laboratory platen presses, RTM resin injection equipment, and industrial and composites curing ovens.

For more information on Intelicare’s full product range, visit their website.

Intelicare

+44 (0)1777 248777

Website

Email