Impact Solutions Expands Analytical Capabilities

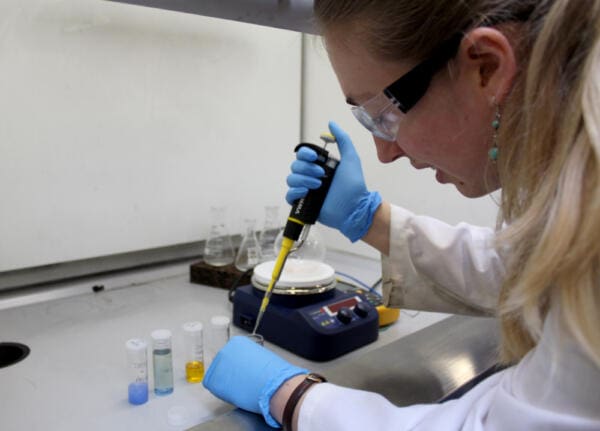

Impact Solutions is committed to providing excellent and reliable testing and certification services to customers across the globe. Building on its already extensive testing capabilities, the company recently completed an expansion to its analytical laboratory.

With new state of the art equipment, Impact Solutions can offer a range of analytical testing such as heavy metal content (cadmium, lead, mercury, etc.), toxicity analysis, RoHS, as well as reveal the content of hazardous compounds which are regulated under REACH. More precisely, Impact Solutions is set up to quantify the levels of persistent organic pollutants (POPs), brominated compounds, phthalates, and other harmful, volatile molecules.

An ICP-OES (Inductively Coupled Plasma – Optical Emission Spectroscopy) unit from Agilent allows Impact to provide quality and accredited test reports on heavy metal analysis. Heavy metals can be present in WEEE recycling components; therefore, testing is vital within this industry. They are not only harmful to the environment but can be toxic to any person who comes into contact with them, such as recyclers working with WEEE recyclate. Heavy metals analysis testing ensures the safety of workers and that components meet the correct regulations for reuse.

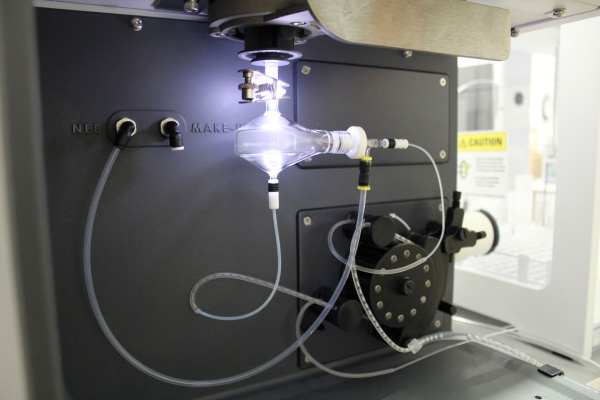

Gas Chromatography and Mass Spectrometry (GC-MS), is an analytical method that combines the features of both pieces of equipment to identify different substances within a test sample. It allows Impact experts to test for complex mixtures of chemicals to be separated, identified, and quantified. This makes it ideal for the analysis of hundreds of relatively low molecular weight compounds found in environmental material. A common test for GC-MS is for the presence of persistent organic pollutants. Our unit is also capable of performing evolved gas analysis via a pyrolyser connected to our GC-MS. This enables us to reveal information about additives, decomposition and failure analysis, and main product identification.

Impact Solution’s new HT-GPC (High Temperature – Gel Permeation Chromatography), a powerful analytical tool, can characterise the molecular weight and molecular weight distribution of a polymer. These values are integral to the development and manufacturing of polymers and can help manufacturers with their R&D process to find the best materials for their product, determining if they may be suitable for a particular purpose. We can look at the degradation of a polymer after it has been weathered to see if its properties have changed. It can give us an indication of what the melt flow might be like.

The latest addition of an Elemental Analyser is a technology which analyses the elemental composition of a material. Detecting and quantifying carbon, hydrogen, nitrogen, oxygen, and sulphur in organic and inorganic substances can provide critical information about a material. In some application fields such as pharmaceuticals, polymers, chemicals, environmental, and energy, even a small deviation from the percentage of allowable trace elements can dramatically alter the properties of the material.

This is only some of the new equipment and technologies that Impact Solutions has invested in over the last ten months. It allows Impact Solutions to test for a wide range of analytical needs, across even more industries. Please get in touch today for advice or direction on your requirements. Impact’s experts are available to help you and guide you through the process.

Impact Solutions

+44 (0) 1324 489 182

Website

Email