ICS Cool Energy’s FLEX Hire Scheme Maximises Energy and Operational Efficiency

|

Getting your Trinity Audio player ready...

|

ICS Cool Energy delivered an energy-efficient cooling solution to a plastics manufacturer’s 5,000 sq ft facility, helping them reduce energy costs and optimise performance. The company, which specialises in producing small and large production runs using single or multi-impression mould tools, installed a reliable cooling system benefiting from ICS Cool Energy’s FLEX membership. With FLEX the manufacturer gained access to a brand-new cooling system with no upfront capital expenditure, along with long-term maintenance and upgrade options to ensure ongoing operational efficiency.

The Challenge

The manufacturer operated a chiller that continuously ran at full capacity, which proved inefficient as the system couldn’t adjust to seasonal changes in ambient temperature. Even during cooler periods, the chiller remained at maximum output, leading to high energy consumption and increased operational costs. This inefficiency was particularly evident in the winter months, when significant energy savings could have been achieved through free cooling.

Due to the substantial cooling requirements of their moulding machines, the company needed a more energy-efficient solution that would allow them to leverage natural cooling and reduce their energy bills. Additionally, they sought a solution that aligned with their preference for long-term rental agreements, avoiding large upfront capital expenditures typically associated with equipment purchases.

The Solution

ICS Cool Energy proposed a free cooling system as part of a flexible, subscription-based FLEX membership that provided more than just new equipment—it included a complete temperature control package.

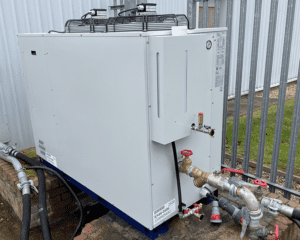

Free cooling allows businesses to recover up to 80% of their process cooling energy costs by utilising lower ambient temperatures to cool their processes, reducing the reliance on mechanical cooling from the chiller. For this manufacturer, ICS Cool Energy installed a 45 kW i-Chiller along with a dry air cooler, allowing the system to automatically switch to free cooling when the external temperatures were low enough, reducing energy usage.

The FLEX membership includes preventive and 24/7 emergency support, replacements, and upgrades, all all tailored to the business’s needs following a detailed assessment by ICS Cool Energy’s engineers.

Unlike traditional long-term hire agreements, FLEX membership also provides the flexibility to exchange and upgrade the equipment as the business’s requirements change or technology advances.

Result

With the FLEX membership and new free cooling system, the manufacturer now operates a highly efficient cooling setup that significantly reduces energy consumption and contributes to reducing the environmental impact of their processes.

The all-inclusive monthly rate scheme with ICS Cool Energy FLEX, covers maintenance, upgrades, and contingency plans, giving the manufacturer peace of mind. In the event of a system failure, the contingency plan ensures rapid access to backup equipment, minimising downtime and production delays.

By choosing this flexible temperature control hire solution, the manufacturer also mitigated the risks typically associated with equipment ownership, ensuring uninterrupted operations while keeping costs predictable.

Read more news on ICS Cool Energy here.

ICS Cool Energy

+44 (0) 23 8052 7300

Website

Email