How IQMS can Help Plastics Processors Grow

Join the Proximity Webinar on Thursday 27 June at 2:00 pm (BST) to learn how IQMS’ can help plastics manufacturers grow.

Over three-quarters of manufacturers cite shop floor productivity improvements as their leading growth strategy for 2019 according to a study conducted by IQMS and Dassault Systemes.

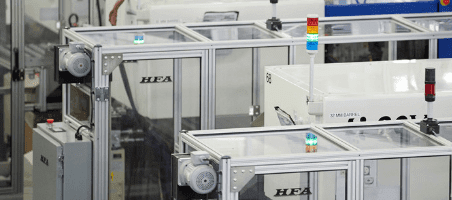

To enable these improvements, machinery upgrades and the purchase of smart, connected machinery dominate investment strategies are required.

Not far behind, however, is the investment in software to manage and schedule manufacturing processes; gain real-time production monitoring; and manage production quality effectively.

Join Tom Grigg, Proximity’s Solutions Architect for a webinar on Thursday 27 June at 2:00 pm (BST) to learn how IQMS’ manufacturing software can help your plastics processing business:

- Achieve greater shop floor productivity and efficiency

- Scale production effortlessly

- Gain operational visibility

- Maintain a competitive advantage.

Register now to learn how IQMS can help plastics processors grow

During the webinar, Tom will focus on three strands within plastic manufacturing production:

- Planning

- Scheduling

- Execution & monitoring

You’ll learn how:

- IQMS’ pre-defined Bill of Materials (BOMs) meet the needs of all plastics manufacturers including injection moulders, blow moulders, extruders, compounders and thermoformers (amongst others).

- You can manage tool preparation and setup to assure your tools, dies and fixtures are ready to run production jobs when they are scheduled. IQMS helps processors to handle simple, complex, progressive and multi-cavity family tools with ease. Tom will also demonstrate how preventative maintenance can also be scheduled for tool wear based on machine cycles.

- Multi and family tool features enable plastics manufacturers to easily manage multiple part numbers within the same physical tool.

- To overcome the complexity of scheduling production efficiently, taking into account the availability of your machine operators, tools and supplies, along with your customers’ deadlines.

- Shop floor monitoring gives you an accurate view of your production. Are you meeting requirements for quality and specifications? Are you meeting (or exceeding) production standards?

Even if you are unable to attend the webinar, still register and you’ll receive a recording shortly after the webinar ends.

About Proximity and IQMS

Proximity is a certified IQMS reseller and provides IQMS implementation services across the UK, Ireland and Europe.

Part of the Dassault Systèmes product suite, IQMS forms part of the 3DEXPERIENCE platform on the Cloud. The platform enables repetitive, discrete and batch process manufacturers to improve operational performance, production efficiency and business agility.

Shortly to be rebranded as DelmiaWorks, IQMS’ in combination with SOLIDWORKS, enables a unique closed-loop manufacturing system – all the way from design through the entire plastics manufacturing process.

Proximity

0113 393 3360

Website

Email