HASCO Solution Stacks Up

With the aim of making production more efficient, increasing use is being made of stack moulds – and not only in cases where production space is limited.

With twice the number of cavities, stack moulds can double the output of moulded parts for the same clamping force and hence ensure more effective machine utilisation. Alternatively, the number of cavities can be kept the same and the clamping force halved, thus reducing the necessary investment and the space required. Stack moulds constitute a technically and economically advantageous alternative to bigger machines or moulds.

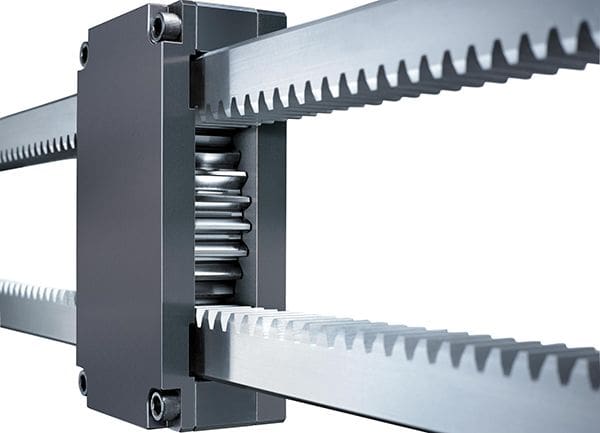

The HASCO stack mould components Z1545/… and Z1547/… have now been supplemented by an additional 2.5 module, making it possible for users to make smaller stack moulds too.

The standardised HASCO components allow the simple, reproducible and inexpensive construction of stack moulds of this type. The low height of the components permits small distances between the tie bars on the machine and also high opening forces through the use of high-quality material.

DLC-coated slideways minimise wear and extend maintenance intervals. All standardised components are available from stock. The use of HASCO stack mould components ensures that the mould production costs remain calculable. This then has a positive impact on item costs and competitiveness.

Find out how the HASCO system could increase your production efficiency. Contact the team on:

HASCO

+44 (0) 132 787 6018

Website

Email