Hand-Finished OEM Badges from Great Central Plastics

|

Getting your Trinity Audio player ready...

|

In the world of automotive, every detail matters. From the sleek curves of the bodywork to the precise alignment of the headlights, excellence is not just a goal; it’s an expectation. At Great Central Plastics, they understand this ethos intimately, and it’s why they go the extra mile in ensuring that every injection moulded automotive badge that leaves their facility exceeds industry standards.

Individually Inspected

At Great Central Plastics, the team take immense pride in their injection moulding process, which allows them to manufacture OEM badges of unparalleled quality and durability. But what sets them apart is their commitment to hand inspection and finishing. While many companies may rely solely on automated processes, GCP believe that the human touch is indispensable when it comes to achieving perfection.

Each badge that goes through the production line undergoes a rigorous inspection by an experienced assembly team. The GCP team meticulously examines every detail to ensure that it meets the exacting standards of the industry. From checking for imperfections to verifying dimensions, their keen eyes leave no stone unturned. This is vital to ensure that custom car badges are in the best possible condition before being sent off for chrome plating, painting, foiling etc.

Hand Finished

But GCP’s dedication to quality doesn’t stop there. Once a badge passes inspection and has come back from chrome plating, it moves on to the finishing stage, where a team of craftsmen employ a blend of traditional techniques and modern technology to achieve flawless results. Whether it’s hand polishing to a mirror-like shine or carefully applying a protective face tape, every step is executed with precision and care.

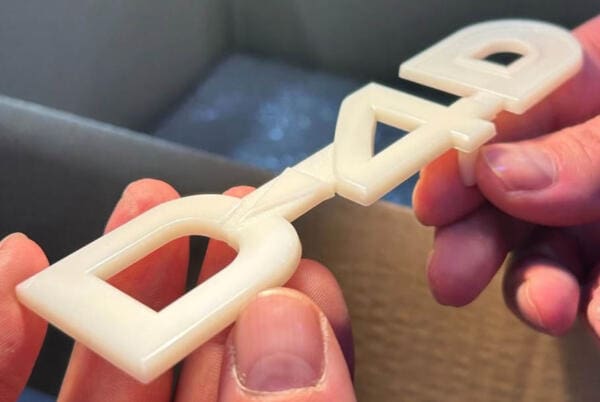

In the example pictured, the D4D automotive badges have come back from chrome plating. They are then inspected before being applied with automotive-grade adhesive. Following this, a die-cut tape is applied to the recess in the ‘D’ where a red moulded ABS badge is also fitted by hand.

Why do we go to such lengths?

Because we understand that the badge on a car is more than just a decorative emblem; it’s a symbol of excellence, a reflection of the vehicle’s identity. Whether it’s proudly displaying a brand logo or denoting a model designation, it deserves to be nothing less than perfect.

By combining advanced injection moulding technology with traditional craftsmanship, Great Central Plastics ensures that our bespoke badges not only meet but exceed the expectations of our customers. Whether you’re a luxury car manufacturer striving for elegance or a performance brand chasing perfection, you can trust us to deliver custom automotive badges that elevate your vehicle to new heights of distinction.

Read more news from Great Central Plastics here.