GJ Plastics Save £2500 a Week with 3D Printing – Case Study

During the pandemic, GJ Plastics, manufacturer of signage and acrylic displays, repurposed production to meet the demand for COVID protection screens. Supported by 3DGBIRE, the agility of additive manufacturing supported existing processes to bring impressive cost savings.

Company

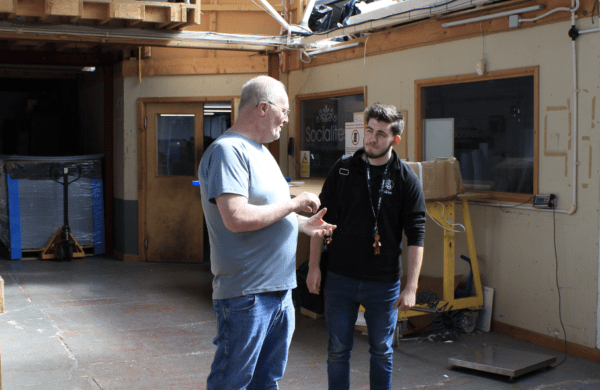

GJ Plastics – Graham Croston, Director

GJ Plastics Ltd is a Northwest-based company with over 30 years experience, producing a large range of acrylic display products, signage, promotional displays and correx printing.

Industry

Design/display products

Challenge

Due to COVID-19 proliferation, Graham saw an opportunity to adapt his products traditionally dedicated to the display market for the protection of people in direct contact with the public. He needed to manufacture COVID-19 protection screens as quickly as possible to market to his clients.

Graham was originally a keen hobbyist 3D printer, and he saw the potential in investing in a dual extrusion printer that would produce virtually ‘injection moulded quality’ components for his company. He was paying £1.50 per unit for one of his components; he aimed to manufacture these in-house, quickly and to save costs.

Solution

By utilising a Raise3D Pro2 Printer, GJ Plastics were able to adapt quickly to supply their customers with ‘COVID-19’ protection screens. The quality superseded that of his previous hobbyist printer and Graham was able to design various fixtures/fixings prototypes to develop cost-effective PLA solutions in-house, rather than having aluminium parts manufactured elsewhere.

“The reason we buy from 3DGBIRE is that not only do they stock a lot of parts for the machine, the support they give is lifetime support. That’s absolutely fantastic – they are only a phone call away and are happy to profile material for us. I give 3DGBIRE 10 out of 10. They are the kind of company you want to deal with.” Graham Croston, GJ Plastics Director.

Results

The RAISE3D Pro2 is one of the best dual extruder 3D printers on the market, delivering excellent print quality and reliable dual extrusion printing. GJ have found the introduction of the RAISE3D Pro2 to be extremely cost-effective and, labour saving. A part that they originally outsourced costing £1.50 per unit is now printed in-house.

In the last ten weeks, GJ Plastics has produced 20,000 of these components costing 25p per unit. A saving of £2500 per week!

Graham has found the printers easy to use and reliable, so much so that they significantly lessen the downtime for production, enabling the company to keep their profit margins. He plans to purchase more machines in the next 12 months.

For full details of this project, watch the video below:

Which 3D printer is for you?

The RAISE3D Pro2 3D Printer – Advanced Dual Extrusion improves on its award-winning predecessor providing next-generation performance. Large build plate volume with unmatched layer resolution and precision. For all your technical support or warranty questions, please reach out and 3DGBIRE will be happy to assist.

About Raise3D

The focus is to inspire industry-level change by designing and building 3D printers that extend the limits of what is possible for designers and manufacturers.

About 3DGBIRE

3DGBIRE are the UK and Ireland’s premium professional 3D printing experts, supplying printers, service, support, training and other market-leading products within the 3D printing industry. We are focused on helping businesses integrate 3D printing into their workflow with the intention of reducing production costs, supporting manufacturing innovation and reducing lead times.

Our team also offer 3D / CAD training.

If you are considering adopting additive manufacturing into your business or would like to find out more, call 3DGBIRE, and speak to an expert.

3DGBIRE Ltd

01257 228411

Website

Email