FourJaw Transforms Fernco’s Factory Insights and Productivity

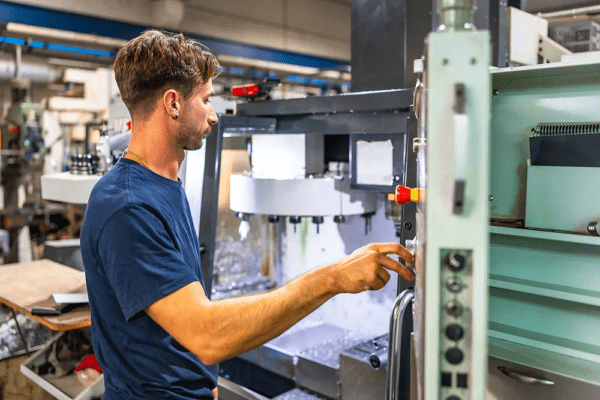

FourJaw Manufacturing Analytics has revolutionised factory insight and productivity at Fernco by automating the capture and analysis of machine utilisation and energy consumption data. By leveraging FourJaw’s advanced machine monitoring technology, Fernco has gained real-time visibility into its operations, enabling data-driven decision-making and improved efficiency across its manufacturing processes.

By implementing FourJaw’s plug-and-play machine monitoring technology at its Barnsley facility, Fernco has improved data accuracy, reduced reliance on manual reporting, and gained deeper insights to support operational decision-making, resulting in a production efficiency improvement of 10%.

Fernco deployed FourJaw’s technology on its injection moulding machines in Barnsley, replacing manual data logging that took several days each month with automated data capture. Real-time alerts now enable faster response times to shop floor issues, while detailed analytics provide a data-driven foundation for decision-making across operations, finance, and senior leadership.

One key benefit has been a clearer understanding of machine utilisation trends, allowing Fernco to make informed decisions on resource allocation and production planning. The data has supported the business in balancing productivity with operational efficiency, ensuring machines are running at optimal levels without unnecessary strain on resources.

Kieran Bestall, Operations Manager at Fernco, comments: “FourJaw has provided us with real-time, fact-based insights into our operations. We can now pinpoint the true causes of downtime, track energy consumption, and make informed decisions about capacity and efficiency. This has helped us establish achievable utilisation targets and better manage our cost base.”

Chris Iveson, CEO at FourJaw Manufacturing Analytics, comments: “We are proud to support Fernco in unlocking the full potential of their production operations. Every factory has unique constraints, and maximising productivity isn’t just about pushing for the highest numbers—it’s about optimising your resources. FourJaw’s real-time data empowers manufacturers to make strategic decisions based on facts, not assumptions.”

Fernco is exploring plans to expand its use of FourJaw’s technology to additional machines to standardise data-driven decision-making across its international operations.

Read more news on FourJaw here.

FourJaw

01144 000 158

Website

Email