Fibrax Process Design Engineer Joins Six Sigma Black Belt Elite

Michael Buckley, a Process Design Engineer at Wrexham-based injection moulders, Fibrax Limited, has achieved the highly coveted Lean Six Sigma Black Belt status.

Michael (pictured, right) was awarded this prestigious status by designing and developing a bespoke production line that incorporates best lean principles. The production line will be used at Fibrax to assemble components used in the highly regulated automotive sector.

Lean Six Sigma is an internationally recognised methodology, combining lean manufacturing and six sigma principles, to reduce defects and waste, and provide a framework for overall culture change and optimisation within an organisation. The black belt certificate signifies a fully trained Lean Six Sigma professional, capable of implementing the methodology in a refined and strategic manner.

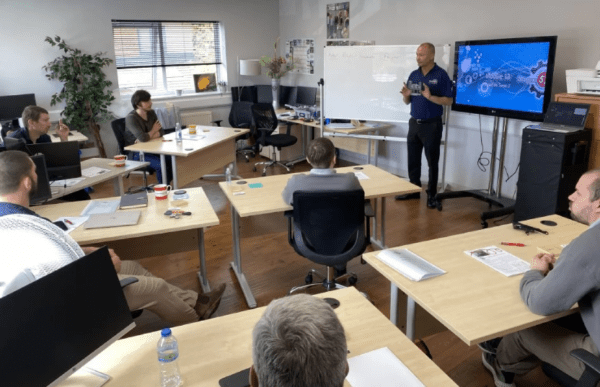

Michael’s production line – the first of its kind at Fibrax – introduces a 1-piece flow, 1 defect flow, 2-bin Kanban system, production control board, 6S (5S plus safety) standard and visual management techniques. Michael used the skills and principles he acquired during an initial training programme delivered by Zenith Lean Training.

Jamie Rimmer, (pictured, left) Fibrax’s Continuous Improvement Manager and fellow Lean Six Sigma Black Belt, mentored Michael throughout the project. Reflecting on Michael’s success, Jamie said:

“From the very outset of this project, Michael has been willing to learn and eager to apply his new skills and best practice techniques to great effect. His enthusiasm made him easy to mentor, and his achievement of black belt status is very well deserved. Congratulations Michael.”

The new assembly line will be used across three shifts, five days a week, to assemble steering column seals supplied to a leading vehicle manufacturer.

Fibrax Limited

+44 (0)1978 356 744

Website

Email