Fern Plastics Invests in Mould Flow Analysis Software Moldex3D

Wolverhampton-based injection moulder Fern Plastics has invested in mould flow analysis with Wilde Analysis to support its customers in optimising the quality of their injection moulded components.

Formed in 1980 and now part of the international PDSVISION Group, Wilde Analysis is a full-service provider of engineering simulation, safety and reliability software, multi-disciplined consultancy and mentoring and training. Its mission is to be your trusted adviser – delivering insight, innovation and confidence through outstanding engineering simulation and risk management software and services – while sustaining a collaborative culture to enable its staff to thrive.

Fern Plastics customises the plastic injection moulding process to produce a bespoke plastic mould product to suit exact specifications and requirements. Since 1959, Fern Plastics has used the process of plastic injection moulding technologies to manufacture prototypes and end production products as part of a comprehensive service both in the UK and Internationally.

A director of Fern Plastics explains the reasons for their investment: “Fern decided to invest in mould flow analysis with Wilde Analysis in order to support their customers in optimising the quality of their parts by identifying any issues arising from part design and material selection early on in a project and before tool design and manufacture. Issues such as surface defects, weld lines, gas traps and warpage could be predicted and solutions found to overcome them as well as identifying optimum gate positions, types and size.

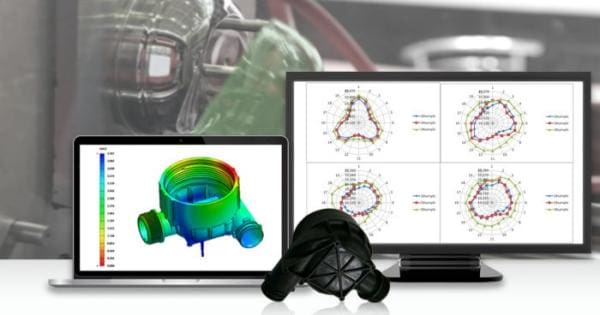

“After demos from several suppliers, Fern chose Moldex3D as the best all-round package to meet their requirements due to its ease of use and comprehensive simulation, visualisation and injection moulding analysis.”

About Moldex3D

Moldex3D is the world-leading CAE product for the plastics injection moulding industry. With the best-in-class analysis technology, Moldex3D can help you simulate the widest application range of injection moulding processes to optimise product design and manufacturability, shorten time-to-market, and maximise product ROI.

Wilde Analysis is a certified Moldex3D channel partner and has used plastic injection moulding simulation software for consulting for over 20 years. Its combined software, training and consulting solutions enable the incorporation of simulation into the design and development processes efficiently, with expert support and mentoring from an experienced and friendly technical services team.

If you’d like to try Moldex3D software, download your free Moldex3D Viewer here.

For further information on Moldex3D software, training and consultancy services, visit www.wildeanalysis.co.uk or talk to one of the account managers about how Moldex3D can benefit you – simply get in touch using the contact details listed below.

Wilde Analysis

+44 (0) 161 474 6886

Website

Email