FDA-approved and ATEX-rated Ancillary Equipment Launched by AB Systems

Fast-growing ancillaries specialist, AB Systems, has once again expanded its product offering following the company’s appointment as the exclusive UK distributor for industry-leading OEM, Simar.

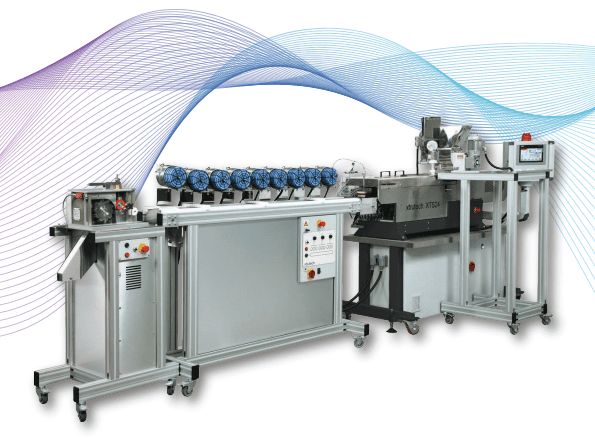

The comprehensive range of Simar materials handling equipment includes FDA-approved and ATEX-rated solutions, and will enable AB Systems to meet wider and more specialist requirements of manufacturers, particularly those within the plastics, food, pharmaceutical, and chemical sectors.

FDA-approved and ATEX-rated equipment is in demand, but criteria for achieving these standards are extremely high. ATEX, for example, is a safety standard that is designed to protect employees from explosion risk, and only equipment with this rating is allowed to be used in environments with potentially hazardous atmospheres, such as those found in some manufacturing facilities handling dust-containing materials and powders.

Consequently, the availability of FDA-approved and ATEX-rated equipment has been limited to a relatively small number of suppliers. With the Simar range, AB Systems aims to give manufacturers more choice when sourcing products.

“Part of AB Systems’ strategy for giving manufacturers access to more efficient, better performing and competitive ancillaries solutions is to bring an increasing, but highly selective, number of OEM brands to the UK market. Simar helps us to achieve this goal. The company’s range of material handling equipment is exceptional in terms of build quality and performance, and carries FDA and ATEX approval. Having worked in plastics, food and pharmaceuticals manufacturing for years, I know that clients will be delighted to have a wider pool of niche products available to them,” explained Milton Shelley, Technical Sales Director at AB Systems.

Simar’s advanced equipment range comprises central conveying systems, dehumidifying and hot air dryers, hopper loaders (and weighing/mixing), crystallizers, and special clean room systems.

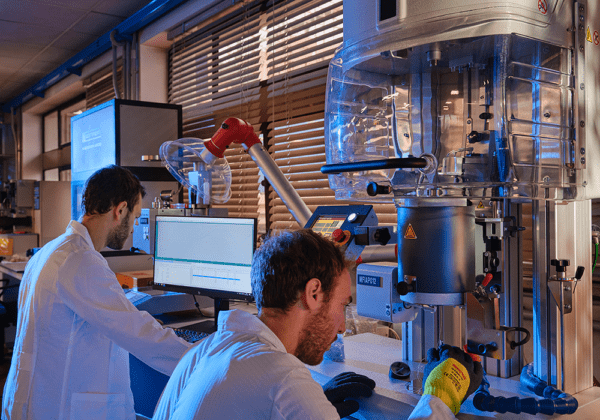

As would be expected, build quality and performance are exemplary, and all products are characterised with Simar’s pioneering innovation. For example, Simar’s new eDry desiccant dryer uses newly developed ECO technology to drastically reduce regeneration frequency from up to seven times per working day to just once, thereby dramatically increasing energy efficiency while minimising wear and tear. The eDry PLC control allows for complete traceability of the entire drying process in real time including dew point, material usage, energy consumption, recipe data base and management, ethernet interface, scheduled maintenance and Industry 4.0 ready, ideally suited for the automotive industry and its suppliers.

Since partnering with Simar, AB Systems has experienced significant growth of its client portfolio, and welcomed a large number of new customers, AB Systems provides a complete ancillaries service to its customers, including system design, installation, and maintenance. The company also holds key serviceable spare parts for Simar equipment at its headquarters facility in Buckinghamshire, affording customers fast repair services.

“We’re delighted to have secured distribution rights for Simar; it has enabled us to fill a gap within the supply, installation and maintenance of superior quality materials handling equipment to the plastics, food and pharmaceutical industries, and brings a new level of innovation to the market,” said Mr. Shelley.

For more information on AB Systems please visit www.ab-ltd.co.uk.

AB Systems

01844 339 044

Website

Email