ENGEL Reactive Unit Now Available in Two Sizes

The ENGEL reactive unit, used specifically for the preparation and injection of ε-Caprolactam, is now available in a new smaller size, enabling its use in a wider range of applications.

In-situ polymerisation opens up great opportunities in the production of fibre-reinforced plastic components with a thermoplastic polyamide matrix. The decisive factor for processing efficiency and product quality is the reactive unit developed by ENGEL specifically for the preparation and injection of ε Caprolactam. ENGEL has systematically further optimised its solution with a new, smaller size.

Now available in small

Now offering two sizes, ENGEL covers an even wider range of applications and supports its customers from product and process development, through scale-up to series production. The new smaller reactive unit can handle matrix volumes between 10 and 600 cm³, offering great flexibility, especially for testing facilities, in the production of test parts, specimens and parts up to a weight of 1.5 kilograms. The second, larger unit can process matrix volumes of up to 1500 cm³. Both units are very compact. They integrate the complete media supply and reduce the footprint required for the entire system.

In in-situ polymerisation, the thermoplastic RTM process, pre-shaped dry fibre preforms are infiltrated directly in the mould cavity with the reactive matrix. Thanks to ε Caprolactam’s low viscosity in a molten state, the dry fibres can be wetted particularly well. Compared to duroplastic RTM, longer flow paths and higher fibre content are possible. When the ε Caprolactam is polymerised to create polyamide 6, a composite with particularly high load-bearing capacity is formed that can be functionalised by injection moulding immediately after manufacture in the same process.

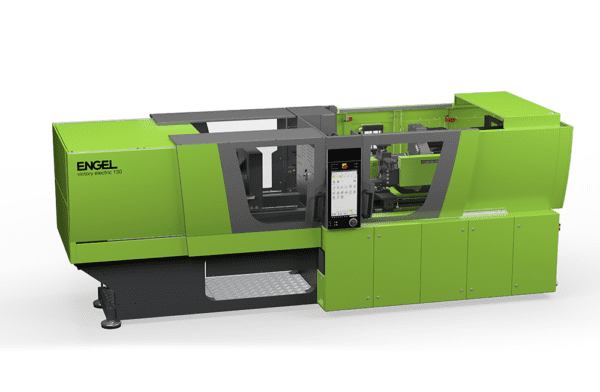

Compatible with all ENGEL injection moulding machines

Both sizes of the ENGEL reactive unit can be combined with ENGEL injection moulding machines from all series. A retrofitting option is available for injection moulding machines with the CC300 control unit. Complete control integration ensures that the entire process can be managed centrally on the machine display. Optionally, the reactive unit can be operated as a stand-alone system with its own CC300 control unit.

The range of applications for in-situ polymerisation extends from small parts with thin wall thicknesses through to large, highly stressed structural elements in lightweight automotive engineering, automotive electronics, technical moulding and sports equipment manufacturing. When overmoulding metal inserts or cables in very small structures, in-situ polymerisation can offer advantages over other processes – even without fibre reinforcement.

For more information about this process, read the full press release on Engel’s website.

ENGEL

+44 (0) 1926 335000

Website

Email