ENGEL | Smooth-Running Plastic Fan Wheels for Electric Motors

Electric cars often have higher demands on the quality of injection moulded components than combustion models. An application example from the automotive supplier Krug shows how ENGEL machines ensure the quality required for this.

The Starting Position

Electromobility presents the injection moulding industry with new challenges. In addition to new applications, the requirements for established vehicle components are also changing. One example of such components is plastic fan wheels for electric motors. In the case of internal combustion engines, the focus has so far been on the greatest possible cooling capacity. Due to the almost noiseless electric motors, the smooth running of the fan wheels now also plays an important role. Even the smallest imbalances and irregularities of the surface can cause disturbing noise while driving. In the past, imbalances in the larger fan models could still be compensated for with clamps. Today, the injection moulding machine must deliver the required precision.

“The demands on the quiet running of the fans have increased significantly over the last three years. Reproducibility and dimensional accuracy are now the most important criteria when we invest in new injection moulding machines.” Rüdiger Braun, Managing Director at Kunststofftechnik Krug GmbH in Germany

The Requirement

Krug GmbH is one of the largest manufacturers of car fan systems in Europe. They produce for OEMs as well as for large automotive groups. The application example considered here is the plastic fan wheel for the electric motor of the Porsche Taycan. The specific requirements for the component of this electric car were as follows:

- Absolutely homogeneous material distribution for maximum running smoothness

- High moulding precision for smooth surfaces and straight component edges to avoid air turbulence

- Reliable plasticising and injection of plastics with high glass fibre content

- High process stability for a maximum proportion of good parts

- High output to ensure the profitability of production at the Breidenbach site in Germany

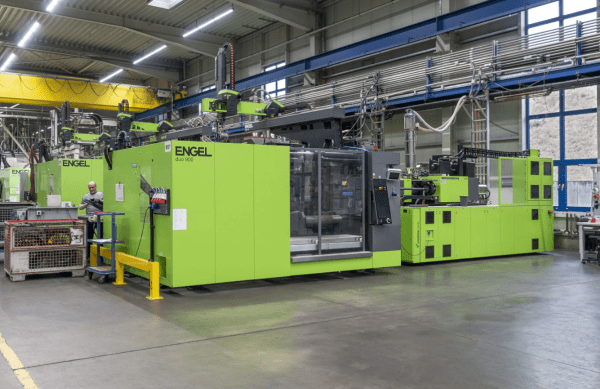

The Machine

Krug contacted ENGEL in search of a suitable injection moulding machine. A two-platen injection moulding machine from the duo series with a clamping force of 9000 kN was selected as the suitable basic machine. The duo’s broad and comprehensive range of sizes made it possible to select the exact machine size for the application. Over-investment in a larger-than-necessary clamping force class was avoided. In addition, the duo series combines precise machine movements with high-efficiency thanks to its modern servo-hydraulics. The energy consumption of the machine was analysed in detail before the purchase decision was made.

Due to its high efficiency, the duo qualified for a government subsidy programme. Initial injection tests on the machine followed with customer moulds, in which pressure and temperature sensors were integrated for each blade of the fan wheel. The results in terms of repeatability and process stability were promising, says Jochen Krug, CEO of the Krug Group: “We have seen that the duo injection moulding machines from ENGEL manage both very well.”

However, it was not only the fundamental properties of the duo that tipped the scales in favour of ENGEL as a supplier, adds Krug: “We see that we really get more out of the machine with the application technology advice from ENGEL and with the training courses offered. Often the machines can do more than you do with them. We want to change that in order to really achieve the maximum in terms of quality.”

The Solution

Due to the many favourable features, ENGEL was awarded the contract by Krug with the duo 900. After installation of the system, the duo 900 proved the customer’s confidence in ongoing production operations. The production of plastic fan wheels for the electric motors of the Porsche Taycan runs efficiently and smoothly. The implementation of the requirements defined at the beginning was solved as follows:

- Absolutely homogeneous material distribution for maximum running smoothness

The precise machine movements of the duo enable exact control of the process and high repeatability. The material is evenly distributed in the cavity. The very tight tolerances of the components are reliably maintained. - High moulding precision for smooth surfaces and straight component edges to avoid air turbulence.

The high precision of the injection moulding machine also enables exact moulding and a smooth. The homogeneous surface of the plastic fan wheels for the electric motors. The components checked by 3D scan correspond to the reference geometry. - Reliable plasticising and injection of plastics with high glass fibre content

ENGEL offers special screws for the plastics used with a high glass fibre content. These enable a consistently high melt quality. The service life of the plasticising components is high despite the very abrasive plastic/glass fibre mixture. Laser-welded carbide layers protect the screw from high mechanical loads. - High process stability for a maximum proportion of good parts

The precise machine movements and the specially adapted plasticising components enable high repeatability. In addition, the digital assistance system iQ weight control ensures fully automatic compensation of process fluctuations even before a bad part is produced. - High output to ensure the profitability of production at the Breidenbach site in Germany

The avoidance of rejects despite tight tolerances enables a high output. The low energy consumption of the entire system also keeps operating costs low. The particularly compact footprint of the duo series also increases productivity per unit area.

At the Breidenbach headquarters, the ENGEL duo is now the predominant machine type for the production of large components. Further duo machines are in operation at the production plants in Meerane in Saxony and Felsőzsolca in north-eastern Hungary.

Read more news from ENGEL here.

ENGEL

+44 (0) 1926 335000

Website