ENGEL | Make Plastics Recycling More Efficient

For us at ENGEL, plastic is a valuable resource that must be brought into a circular economy. That is why we are constantly researching and developing new technologies in order to be able to make greater use of recycled plastics. The new plastics recycling process makes a contribution to this.

With the help of a newly developed two-stage process our injection moulding machines can now process plastic waste directly after granulation. Thus an entire process step can be eliminated, what reduces recycling costs and improves the CO₂ balance.

Conventional plastics recycling vs. new recycling process in two stages

As with the new plastics recycling process, also in conventional recycling plastics from post-consumer and post-industrial collections are used. These are sorted, cleaned, granulated, compounded, and fed into injection moulding as regrind.

The granulation step in particular consumes a lot of energy and is associated with a high logistical effort. According to our calculations, the energy requirement is reduced by 30 % if this step can be skipped.

In our two-step process, this granulation step is no longer necessary. Plastic flakes are used directly as the raw material. Plasticising and injection are divided into two independent, coordinated process steps.

1st stage: The raw material is fed into a classic plasticising screw. There it is melted.

2nd stage: The resulting melt is transferred to the injection screw to be injected into the cavity in the second process stage. During this transfer from the plasticising to the injection screw, impurities can be removed. A melt filter and a degassing unit are integrated for this purpose. In this way, even contaminated plastic waste can be used and processed into high-quality products.

This innovation not only shortens the recycling process, it also reduces the costs, saves CO₂ and it means another step towards building a circular economy for plastics.

What is special about the two-stage plastics recycling process?

The special feature is the degassing unit. It forms the transition from the plasticising screw to the injection screw and consists of a transfer head through which the melt is pressed. This increases the surface area of the melted material and in this way only partially fills the injection screw.

Volatile components can thus easily leave the melt. In addition, it is possible to work with negative pressure generated by a vacuum pump. This may be necessary if the application or the degree of contamination requires it.

Degassing is an essential step to ensure consistently high quality. This is because certain impurities cannot be caught in the melt filter. These include:

- Residual moisture and

- low-molecular compounds from material degradation or printing ink residues.

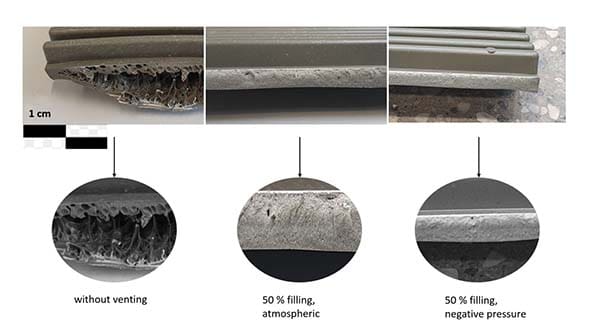

They can cause pores inside and defects on the surface of the component. All this reduces the mechanical strength of the component and must be taken into account in any plastics recycling process.

Is the 2-stage plastics recycling process also suitable for large shot weights?

Yes, it can be adapted for processing very large shot weights of up to 160 kg. Here, the plasticising screw is combined with a piston unit instead of an injection screw.

The two-stage process also proves to be advantageous here compared to a conventional plasticising and injection process:

- The design of the system can be more compact.

- Lower unit costs can be achieved.

A typical disadvantage of piston injection units is the change of material. ENGEL has therefore developed a new plunger design and optimised the plunger tip to enable flow. This supports the uniform flushing of the plunger and enables a rapid change of material and colour.

The adapted plastics recycling process can be used from a shot weight of 20 kg. Even from this weight, the processing efficiency increases significantly due to the splitting of the plasticising and injection process. Applications include containers, pallets or large fittings.

Does the new plastics recycling process have an impact on quality?

To demonstrate the potential of the two-stage process, the new degassing unit was tested in extensive trials.

Test series: The test series took place at ENGEL’s technical centre in St. Valentin, Austria. The results were evaluated at the CHASE Competence Centre in Linz, Austria. Three different materials were used in the tests:

1. deliberately contaminated PP virgin material

2. PP agglomerate from post-consumer films

3. regrind from HDPE beverage closures

Result of the tests: The quality was consistently high for all three materials. The achieved properties of the products are thus in no way inferior to the conventional plastics recycling process. The two-stage process also achieved better degassing of the raw material.

In addition, the trials have provided further insights:

- The sample parts produced without degassing had very large pores in all three materials. Degassing the melt significantly improved the part quality.

- Degassing performance improves when the surface area of the melt is increased. The size of the surface area can be controlled by the degree of partial filling of the injection screw.

- The speed of the injection screw has hardly any influence on the degassing performance. Even heavily contaminated raw material can be processed at high speeds. This means that short metering times are possible without any problems.

- Regrind and agglomerate from pure post-consumer collections can be processed in a process-stable manner. The shape of the raw material flakes is irrelevant for the product quality, only the flowability is essential.

Would you like to know more about the plastics recycling process? Our experts will be happy to advise you. Contact us here.

Read more news from ENGEL here.

ENGEL

+44 (0) 1926 335000

Website

Email