ENGEL | Dry Cycle Time Around 10% Shorter

The better the motion sequence, the higher the performance. In the form of iQ motion control, ENGEL has developed an intelligent assistance system which automatically optimises the acceleration phases to support faster movements.

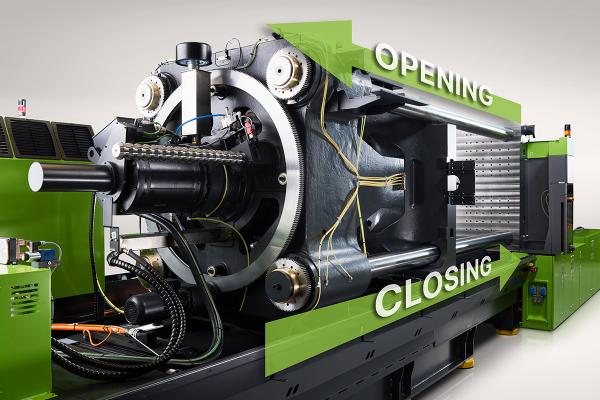

In high-performance applications, this can significantly shorten cycle times and provide a competitive advantage. In high-speed applications, the time the injection moulding machine takes to open and close the mould is a part of the cycle time. Like a robot arm, the moving mould mounting platen on the injection moulding machine does not simply open and close; instead, it follows individual motion points. These points split the movement into phases, precisely where the key to optimisation lies. For each individual phase, iQ motion control software computes the optimum acceleration for the matching machine setting.

The best possible motion for every application

The basis for the calculations is the configured mould stroke, clamping force, and mould weight. iQ motion control optimises autonomously at the push of a button. The software optimises the acceleration phases, increasing the speed of the platen by doing so. This allows for faster part removal and, in turn, a shorter cycle time.

The injection moulding machine does not require additional energy for this performance boost. Higher connected loads are not needed. The software leverages the existing potential of the machine and the drive technology to the max without increasing the load on the machine and the drives.

When adjusting the opening stroke or during a mould change, for example, the motion ramps are often not optimally readjusted due to the pressure of time, or a reserve is configured due to the different mould weights. iQ motion control makes this a thing of the past. No matter which parameter changes, the best possible trajectory is continuously computed, utilising the physical limits, to achieve the shortest possible cycle time.

Proven live at the October 2022 K Show

ENGEL demonstrated how iQ motion control works in practice on its stand at the K show back in October with a sophisticated packaging application. An ENGEL e-speed injection moulding machine produced 125-ml round containers from rPET with a 4-cavity mould using thin-wall injection moulding and in-mould labelling. These containers are used for packaging foods. And the cycle time is accordingly critical for the producer’s competitiveness.

Analysis of the cycle time has shown that mould opening and closing account for a particularly high proportion of the total cycle time in this high-performance application. Without iQ motion control, the time required for mould movement is 1.27 seconds. With iQ motion control enabled, the machine only needs 1.12 seconds for mould movement. This is equivalent to time savings of 12%. The reduction for the total cycle time is 5%, with a drop from 3.15 to 3 seconds.

A standard feature of new machines and available for retrofitting

iQ motion control will be included in the standard feature set of all new electric toggle-lever injection moulding machines in the ENGEL e-cap and e-speed series and can be retrofitted to older machines. e-cap and e-speed injection moulding machines are used in high-performance applications in the packaging and medical technology industries. Thanks to iQ motion control, these machines achieve a dry cycle time that is around 10% shorter.

Read more news from ENGEL here.