Emerson ‘Clean’ Welding Technologies Create New Aesthetic Opportunities in Complex Assemblies

Through its Branson™ plastic welding systems, Emerson is opening new creative opportunities for designers of multidimensional plastic parts, both large and small, within the automotive, medical and personal electronics industries.

Today’s automobiles are remarkably sophisticated, with high-tech lighting inside and out, thousands of sensors, radar and cameras.

Wearable medical devices, including heart-rate and blood-pressure monitors, insulin-delivery devices and even fitness trackers, as well as consumer and business electronics like miniature audio devices, telephones, cameras and touchscreen devices all represent precision 3D assemblies that incorporate sophisticated electronics.

They all demand durable, hermetically sealed welds that meet the highest standards for style and aesthetics, with clean, precise weld lines with no flash while avoiding damage to delicate built-in electronics.

In many cases, proven welding techniques like ultrasonics, spin welding and even conventional vibration welding, which work well in many simpler applications, fall short in applications that involve newer materials, 3D shapes, or delicate electronics that can be damaged by the high-frequency motion needed to complete the bond. However, Emerson offers three “clean” Branson processes that are creating exciting new opportunities. They are Contoured Laser Technology (CLT) and, sometimes, Clean Vibration Technology (CVT) and PulseStaking.

How They Work

Contoured Laser Technology

Branson Contoured Laser Technology from Emerson is ideal for welding entire assemblies that incorporate not only the plastic components but also sophisticated lighting, delicate sensors, cameras, or other electronic components that could be damaged by the mechanical motion of ultrasonics and other less versatile techniques.

Unlike trace or scan lasers that must travel the entire length of the weld line, completing the weld a little at a time, CLT involves multiple beams positioned on many axes so that the energy is delivered along the full length of the weld surface at once. CLT can weld dozens of different polymers, including some of the most advanced engineering and reinforced materials. And it does so without possibly harmful vibration.

Clean Vibration Technology

Branson Clean Vibration Technology from Emerson represents an alternative to laser welding but also delivers many of the same benefits. Unlike more conventional vibration or ultrasonic welding, the heat energy required to melt and weld the components is delivered during an infrared preheating operation that plasticises the weld line. Only then are the two components brought together under pressure so that vibration can complete the weld. This two-step process requires no solid-solid friction, which ensures uniform material flow and prevents particulate generation. Because the vibration portion of the process is less intense, there is much less chance of damaging delicate embedded components.

PulseStaking

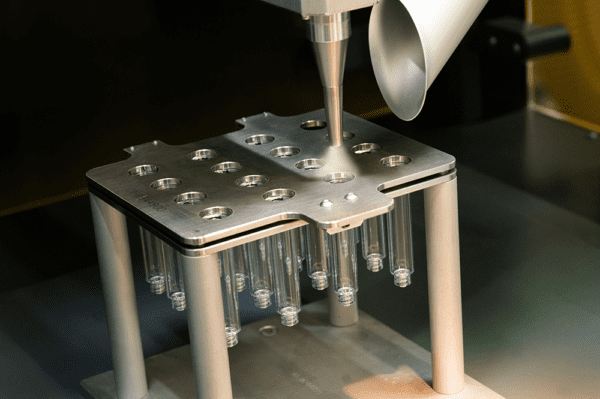

Branson PulseStaking Technology from Emerson is especially advantageous when it comes to arranging and securing many small and often sensitive electronic items into component-dense plastic structures in automotive, medical and electronics applications.

Staking involves placing components onto small posts in a plastic part, then reforming or ‘staking’ the exposed posts using heat and force into flattened, rivet-like disks that lock the components in place.

Unlike traditional thermal staking, which continuously radiates high heat in all directions before, during and after a stake, PulseStaking applies heat only momentarily and locally. Stakes can be made quickly and at a relatively low cost, capturing and securing components made from many materials: plastics, glass-reinforced polymers, metals, ceramics, fabrics and filter media, and even printed circuit boards (PCBs), switches and electronics.

Conclusion

Emerson welding technologies can help improve every part of the production and performance of your large (and small) components, no matter how complex. The process-neutral range of Emerson plastic welding technologies offers more options and applications for smarter joint design, providing long-term durability and performance.

For more information about the latest Branson welding solutions, visit Emerson.com/Branson. Click here to read more articles from Emerson.

Emerson

+44 148 375 8165

Website

Email