Energy Saving Dryer Gets Approval from Automotive Suppliers

When Simar were approached by several companies who manufacture components for the automotive industry in Germany to design and manufacture a dehumidifying dryer that suited all their requirements, the Simar engineers designed the dryer around three main points: energy savings (up to 40% on conventional dryers); quality and reliability (24/7 operation); and industry requirements (Industry 4.0).

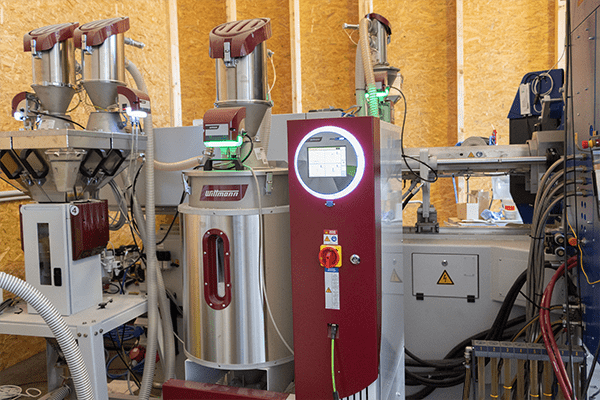

After new and innovative design changes and months of extensive running in 24/7 production environments the SIMAR e-DRY was launched and given awards for example, from the German Federal Ministry for Economy and Environment and The Association of Donors for the German Economy.

To summarise some of the excellent features of the e-Dry:

Energy saving and amortisation

The average energy saving of an e-DRY dryer as compared to the traditional desiccant dryers is about 30%. This results in a substantial reduction in the operating and production costs. The costs resulting from maintenance and shutdown times are often underestimated. The longer service life of the molecular sieve and the concomitant lower maintenance effort results in additional cost savings.

The integrated recipe database makes drying recommendations for more than 60 common commercial plastics available. This information serves for determination of the optimum operating parameters during the drying process.

“The e-DRY can do even more!”

– Dew point progression of the process air

– Throughput of dried plastic granulate per drying tower

– Energy consumption of the dryer as well as all the individual components (e.g. regeneration heating)

– Fault message memory with entries of all the operational faults, warnings and maintenance notifications

– All user access, through which every operational setting or every change can be traced

– Industry 4.0 compliant.

The integrated recipe database makes drying recommendations for more than 60 common commercial plastics available. This information serves for determination of the optimum operating parameters during the drying process.

Operational safety and maintenance

Apart from the reproducibility of the drying process, the operational safety is another important aspect. Unexpected downtimes of the drying plant often result in hindrances in the production flow. Regular maintenance work is a precondition for fault-free dryer operation.

Throughput measurement and dwell time control

Taking into account the replenishment quantity that has been set for every charging cycle, the granulate throughput is calculated and set in relation to the specified drying time. If the drying time is undershot, warnings are output and logged.

The actual throughput of dried plastic granulate per drying tower is continuously updated and displayed.

Weekly timer

The weekly timer makes it possible to match the power-on and power-off times of the dryer to the operational production times. Continuous or day operation can be defined individually through freely programmable cycle times.

Network connection for remote access or for remote maintenance

Apart from the USB port, every e-DRY has an ethernet port as a standard feature. The dryer can be controlled and observed from one or more in-house PCs over a network connection.

Almost independently of the location of the dryer or the place where the operator is stationed, the e-DRY can be controlled remotely from a smartphone, tablet or laptop.

Load-dependent regulation of the process air supply

The process air is fed to the respective drying tower according to need, through motor-driven regulating flaps. According to the moisture loading of the material to be dried, the dry air is fed in a regulated manner. This protects the plastic granulate from over-drying and simultaneously reduces the energy used.

Over-drying protection with SDS (SafetyDryingSystem)

As long as an individual processing machine is assigned directly to a drying tower, an exchange of signals between the processing machine and the dryer can be used to stop or interrupt the drying process. In this manner, the granulate can be protected from over-drying, for example, if there is a machine shutdown, and the energy consumption reduced.

Quality and Environment Management

Many companies specify strict requirements in the areas of quality assurance or environment management. Often, the quality assurance has to be documented and depicted as part of audit requirements. The environment management system requires the recording and evaluation of the relevant process data and is responsible for the coordination and planning of the ongoing improvements with regard to important environmental aspects or binding obligations.

The advantages of every e-DRY dryer become apparent here as well, be it through the reduced energy consumption or, for example, through the recording and provision of all the process data.

The e-DRY dryer is available in the UK through Simar’s distribution agent AB Systems. Get in touch with AB Systems for more information.

AB Systems

01844 339 044

Website

Email