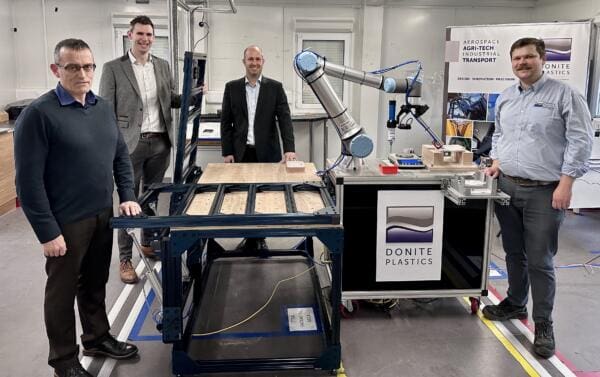

Collaboration is Key for Donite Plastics and KrushTech

Michael Knight, Managing Director at Donite Plastics, is delighted to have worked with Galway-based firm, KrushTech, to manufacture parts for one of its advanced crushing machines.

Specialising in industrial thermoforming, Donite Plastics teamed up with KrushTech, a company that designs and builds advanced crushers for use primarily in the material and handling sector, to manufacture the protective covers for the EcoKrush 6040 range.

The new EcoKrush 6040 machine aims to reduce waste on construction and demolition sites, and one has already found itself on its way to a company based in Germany.

Michael Knight said:

“We’re delighted to be working with KrushTech, a company that is seeking to be one of the best in its field. We at Donite Plastics pride ourselves on the fact that our products can be designed and manufactured in-house.

“Using our Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, our engineers closely worked with the team at KrushTech in the design of the protective covers to create the tooling needed to manufacture the finished product.”

Michael Barton, Sales Manager at Donite Plastics, added:

“Using industrial thermoforming to manufacture covers is becoming increasingly popular as opposed to glass-reinforced plastic (GRP). The method of industrial thermoforming has many advantages for the customer.

“It reduces the weight of products without compromising on durability or strength. It allows for small and large parts to be manufactured in a short lead time and the parts are fully recyclable. The design is also adaptable and the ability to produce larger volumes of products means that our customers are guaranteed value for money.”

Michael Knight concluded:

“We’re so pleased to have been able to deliver high-quality parts for KrushTech; the mobile compact crusher is a great feat of engineering and can be used in the smallest of spaces. We are very proud to have played our part in helping KrushTech deliver this amazing piece of machinery.”

Brendan McGrath, KrushTech Managing Director, said:

“Delivering machines that have been manufactured to the highest possible standard is at the heart of what we do at KrushTech. Therefore, it was vital for us to collaborate with a company that shared the same values and work ethic.

“We enjoyed the entire process from working with the Donite Plastics’ engineers to receiving our final product. We’re confident that our EcoKrush 6040 range will meet the needs and requirements of our customers.”

Donite Plastics

+44 (0)28 9263 9995

Website

Email