DMN-WESTINGHOUSE’s Future-Proof Solutions

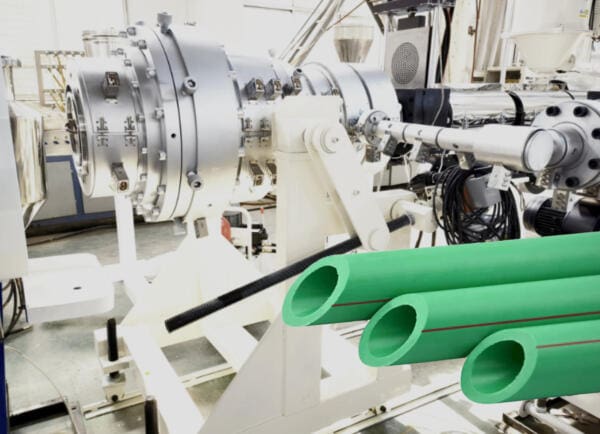

Plastic is a crucial packaging material for food and drink producers and retailers worldwide. It is prized for its lightweight, strength, flexibility, and ease of printing. Plastics enhance the transport and use of products. A recent study revealed that over 8 million tonnes of plastic are used in European food packaging annually. This underscores the plastics industry’s pivotal role in supporting food and drink producers. Explore DMN-WESTINGHOUSE’s future-proof solutions for the plastics industry, enhancing process reliability. Whether you’re dealing with virgin plastic pellets, recycled regrind, or anything in between.

Custom-made Solutions for the Plastics Industry

No two factories processing plastics are identical. As such, there isn’t a one-size-fits-all solution. This is why DMN-WESTINGHOUSE is dedicated to guiding customers through the system configuration process, offering tailor-made solutions for every unique situation.

Additionally, they provide training and consultation for staff to ensure smooth, trouble-free operations. Their most frequently utilised rotary and diverter valves for the plastics industry are:

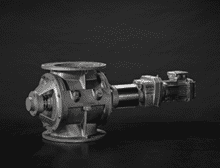

GL – Granular Rotary Valve

A premium quality rotary valve that sets the standard for processing plastic pellets.

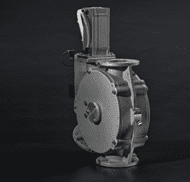

AL- High-duty Rotary Valve

A rotary valve that offers ultimate flexibility for processing recycled ingredients.

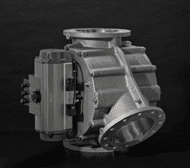

PTD-II – Dual Pipe Plug Diverter

An all-round diverter valve for conveying and diverging plastic ingredients.

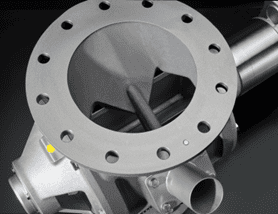

SPTD – Single Straight Pipe Diverter

A single-direction diverter for conveying a wide range of raw materials for plastics.

Trouble-free Operation with their Custon-made Solutions for Handling Plastics

DMN-WESTINGHOUSE offers solutions for both the production and recycling of plastics. Over the years, they’ve crafted specialised rotary valves and rotor models designed to manage virgin plastic powder, recycled regrind, flakes, and granulated plastics.

Their rotary and diverter valves are fine-tuned to prevent powder clogging and to protect granular products from breaking. As they ensure uninterrupted operations, they also prioritise minimising product degradation, empowering plastics manufacturers to utilise recycled raw materials in the most sustainable manner.

Going for Optimal Conveying Quality

In plastics production, the quality of the product stands or falls with how the pellets are conveyed through the production process. The better the pellets stay in shape, the better they will melt into the proper consistency to create perfect plastic parts, like bottle caps or smooth foils for packing food products or lining the insides of drink cartons.

Pellets can degrade during conveying due to different causes, like inaccurate rotor speeds, incorrect filling volume, awkward filling angles, and inconsistent system pressure. Degraded pellets can clog the rotors and cause cross-threading of material, disrupting the flow and leading to blockages. Their focus is to prevent all this from happening. Their products and solutions are proof of this.

When opting for their GL rotary valve you’ll see a marked improvement in product quality output. A prevalent issue when feeding rotary valves with granular materials is the degradation of product quality. Pellets can shear when trapped between the rotary valve blade and its housing. They have analised the flow of particles from the conveying pipes into the rotary valve. Consequently, we’ve designed a distinctive inlet to guide particles, preventing them from colliding with the rotary valve. This significantly reduces the number of broken or sheared products. Additionally, the inlet restrictor could be retrofitted to an AL rotary valve to achieve the same results.

GL rotary valve.

Designed to maintain product quality

Handling Abrasive Materials

Another challenge in conveying raw materials for plastics is the wear caused by abrasive materials. Calcium carbonate, a widely used material in the plastics industry, is notably abrasive. This affects the lifespan of standard rotary valves. DMN-WESTINGHOUSE’s rotary valves have undergone treatments to withstand such abrasive materials. Some of their customers process up to seven tonnes of dry bulk material per hour. Beyond a guaranteed twelve-month trouble-free operation, their valves can typically remain operational for up to two years. This highlights how integral the quality of their valves is to their customers’ production processes.

Allow DMN-WESTINGHOUSE to Engineer Your Plastics Production Process to Perfection

It’s time to move past the issues of clogging, cross-threading, and blockages. DMN-WESTINGHOUSE can engineer your plastics production process to perfection. Increase your output, improve quality, and implement solid solutions today that keep you one step ahead of future requirements and regulations.

Read more news on DMN-WESTINGHOUSE here.

DMN-WESTINGHOUSE

+44 1249 818 400

Website

Email