DMN-WESTINGHOUSE: Committed to Your Success

|

Getting your Trinity Audio player ready...

|

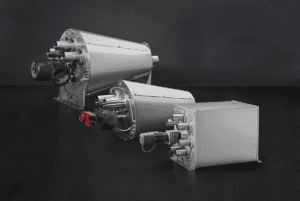

Rotary valves: ensure efficient system operation.

DMN-WESTINGHOUSE offers two advanced designs: Drop-through and blow-through.

Drop-through valves are ideal for gravity and pressure applications. These valves let the material fall through the inlet, move through rotating vanes, and drop out from the bottom outlet flange. They are perfect for applications requiring multiple rotary valves in series on a single conveyor line, ensuring smooth conveyance and maintaining product quality. Easy cleaning without dismantling connections simplifies maintenance.

Blow-through rotary valves are designed for pneumatic conveying lines. These rotary valves have an outlet that fits directly into the blow line, making them great for handling sticky materials like cocoa, flour, or milk powders. Their low-profile design reduces stack-up heights and ensures efficient discharge of cohesive materials. Due to potential wear, they are not recommended for highly abrasive applications or series installations.

The DMN-WESTINGHOUSE rotary valves are available in both heavy duty and medium duty versions. Heavy-duty rotary valves handle up to 2 bar pressure differences and can operate efficiently with product temperatures up to 600°C. They feature an outboard ball-bearing design for simplified maintenance and better protection against product leakage. They are suitable for demanding applications where durability and high performance are crucial, such as heavy industrial processes and extreme environments. They can also be ATEX-certified and EHEGD-compliant, meeting stringent standards for explosive environments and hygienic design.

Medium-duty rotary valves are suitable for lower pressure differences and standard operating temperatures. They offer efficient and reliable performance for general industrial use, where standard durability and reliability are sufficient, such as in cereal, power, LEV, and food processing environments. These rotary valves are ideal for less abrasive materials and industries with less stringent hygiene requirements, providing a cost-effective solution for typical industrial applications.

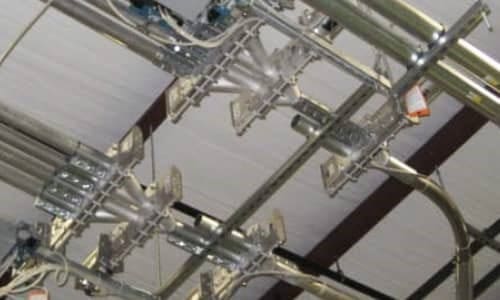

Diverter valves: optimise your material flow.

The diverter valves excel in systems requiring precise routing of dry bulk solids through pipelines. Whether switching between different types of pet food kibbles or managing complex ingredient streams in an industrial process, their diverters offer versatility and efficiency. They help maintain product quality by transporting granules, powders, or pellets with minimal degradation, preserving integrity, and reducing loss. They also enable cost-efficient automation by rapidly switching material flow between destinations on demand without manual intervention, saving time, energy, and labour. Flexible configurations allow routing from one inlet to multiple outlets (diverging) or from various inlets to one outlet (converging).

The range of diverter valves includes plug diverters and tube diverters, available in various sizes and configurations. Their BTD ball-type diverter is durable and reliable, ideal for handling highly abrasive materials. Plug diverters are available in dual pipe, single pipe, and gravity configurations, with some models meeting USDA Dairy standards, making them perfect for food and dairy applications. Tube diverters, with 2 to 14 ports, can be customised to fit specific needs, offering versatile solutions for various applications.

Meet DMN-WESTINGHOUSE. A company distinguished by a culture of dedication, reliability, anticipation (proactive and innovative) and responsibility for people and the environment.

Contact DMN-WESTINGHOUSE today to learn more about how our solutions can be tailored to your needs.

Read more news on DMN-WESTINGHOUSE here.

DMN-WESTINGHOUSE

+44 1249 818 400

Website

Email