3 Signs That You Are Ready to Digitise Your Factory | Intouch Blog

|

Getting your Trinity Audio player ready...

|

If you’re looking to implement smart factory technology you’re not alone. Many other companies are faced with the same challenges and are making the switch to stay competitive. In this blog, Intouch explores three clear signs that indicate your factory is ready to embrace digitisation to enhance efficiency, improve production, and significantly reduce costs.

But is your business ready for it? Here are three signs that you should be making the move:

- Are you experiencing production bottlenecks?

- Is it hard to keep up with production demands?

- Are you looking for ways to reduce costs and increase efficiency?

If you have answered yes to any, or all of the above then it’s time to start considering smart factory technology as a way to improve your operations, and a lot more too.

Many manufacturing businesses are put off leaping digital because they fear the associated costs.

Let’s bust the myth right now! Digitising your factory can be very cost-effective, and potentially low cost too. It’s not a capex expenditure, so potentially easier to find the budget. And most importantly you are likely to see a substantial ROI within weeks.

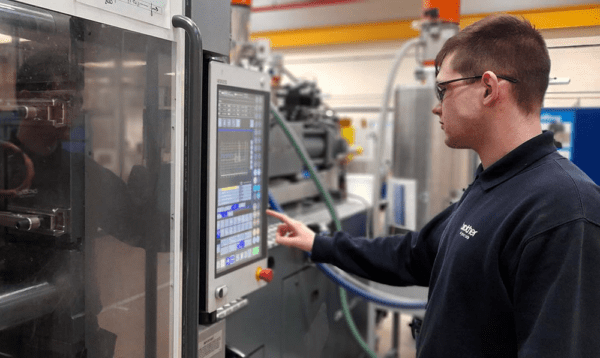

1. Production bottlenecks could be a sign you are ready to digitise your factory:

A bottleneck in a sequence of processes reduces the capacity of the whole chain. Any situation on a factory floor that diminishes productivity is a bottleneck that can cause lost revenue and reduced margin, plus many other impacts too.

Bottlenecks can happen due to any number of reasons:

- Equipment issues

- Staff issues

- Late orders

- Inefficient planning

- Supply chain issues

- Late delivery of raw components

So often this is due to not having a clear overview of your production and the ability to quickly and efficiently make changes.

A lack of visibility on what tasks are taking place at any given time can lead you into solving one problem only for another issue to arise later.

How can digitising your factory help reduce bottlenecks?

- Scheduling equipment maintenance at the best time to minimise production disruption

- Monitoring your production lines with downtime alerts means you can respond and fix the problem and keep production running smoothly

- Digitising your schedule so that jobs are fitted in to maximise capacity

- Ability to add last-minute orders and rearrange the schedule so that all orders are produced on time

- Reports and analytics that highlight any issues so you can make the changes necessary to make production more efficient and avoid bottlenecks

- 24/7 visibility from any device

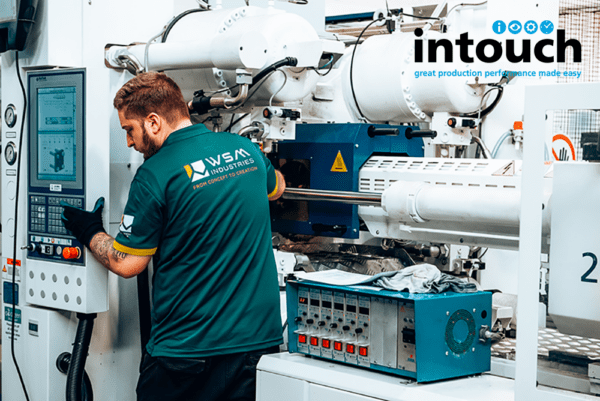

2. Struggling to keep up with production demands is a key sign you are ready to digitise your factory:

Sometimes increasing production does mean having to buy new equipment or hiring more staff but more often than not, manufacturers can get between 6-30% more productivity from their existing resources just by digitising their factory.

Investing in larger premises, new equipment and finding more staff is costly and time-consuming. But turning down business due to lack of capacity isn’t what most businesses would prefer to do, after all the hard work and investment to bring in new business.

So if you’re struggling to accept new orders or get your orders out in time and you aren’t ready to increase your resources, then investing in production monitoring software can instantly increase your capacity. You can achieve more with less (or use your existing resources).

3. If you wish to reduce costs and increase efficiency this is the third sign you are ready to digitise your factory

Costs of material, rent, energy, and labour are all spiralling, and that doesn’t look like changing any time soon. It has never been more important to ensure that you are not wasting any of it but it is very easy to waste significant amounts when there are so many moving parts in a factory. What seems like ‘little wastes’ multiplied by a lot soon adds up to a significant amount of lost profit and margins.

There are lots of ways that digitisation can reduce costs and increase efficiency, but here are some examples:

- Having a clear and accessible digital production plan to alert the job setters to have the machine ready for when production is ready to start. One customer improved changeover times by 10-30% which considering they have over 170 changes a week has had a significant positive impact.

- Reducing scrap by pinpointing the actual reasons for scrap and working to resolve it – our customers reduce their scrap significantly. Without a reliable record that highlights the issue, it is impossible to know what is causing the scrap and how to fix it.

- Setting up a tool that is running for example 20 seconds too slowly because someone forgot to adjust the robot speed can mean you lose 20% of the expected production for that day. With digitisation, managers can easily pinpoint the reason behind the slow speed cycle and make sure it doesn’t happen again.

- Energy loss. Leaving machines on when they’re not being used is a needless energy drain. Alarms that alert staff when machines have been left on prompt them to switch them off.

Take your plastics manufacturing to the next level

If you’re experiencing any of the above issues, it’s time to invest in smart technology.

Smart technology can help resolve production bottlenecks, keep up with production demands, and reduce costs.

If you’d like help digitising your manufacturing operations or assistance in improving efficiency and productivity, please get in touch.

Read more news from Intouch here.

Intouch Monitoring

+44 (0) 1604 537100

Website

Email