Donite Plastics: Major Developments Lie Ahead for the Thermoforming Sector

Ahead of Interplas, which runs from September 28-30, Ireland’s leading industrial thermoforming company Donite Plastics is predicting major developments for the sector over the coming years, citing lightweighting, part reduction, and innovation.

Donite Plastics specialises in the design and manufacture of custom moulded plastic parts using vacuum forming and other processes, ideal for large, medium or small batch quantities and even one-off prototypes. With full CAD/CAM design and manufacturing facilities, and in-house mould making, Donite Plastics turns ideas into production parts within weeks or days rather than months.

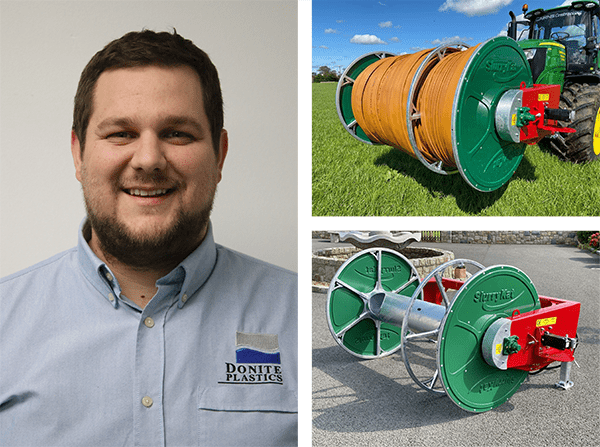

Stephen Kissick, Business Development Manager at Donite Plastics, which is also celebrating its 40th anniversary this year, claims that new developments are in the pipeline for the industry, namely centred around lightweighting, part reduction and innovation.

According to recent research reports, the global thermoformed plastics market is expected to grow at a Compound Annual Growth Rate (CAGR) of 5% by 2026. Meanwhile, the global agri-tech market is expected to grow at a CAGR of 12.1% by 2027.

With this expected growth in the market, Stephen claims that lightweighting, part reduction and innovation will be essential in terms of the sector’s sustainability going forward. Stephen said:

“Sustainability and implementing processes which help to reduce our carbon footprint are extremely important to Donite Plastics.

“What we are seeing from our customers across all sectors, including agri-tech, is that they want materials to be lighter in weight which will reduce fuel consumption, alongside a reduction in costs and labour pressures. Innovation has always been at the forefront of the industry but even more so now as customers search for new and more sustainable ways to solve their manufacturing problems.

“At Donite Plastics, we moved away from Glass Reinforced Plastic (GRP) products some years ago in favour of thermoformed plastics which are more lightweight, robust, cost-effective and can be developed in a quick turnaround time. Our products also stand the test of time and can be repeatedly used; we don’t believe in manufacturing single-use plastics.

“With the projected growth in the global thermoformed sector coupled with the growth of the global agri-tech sector, it’s essential that the industry as a whole moves towards manufacturing products which are lightweight, fuel-efficient and innovative in order to remain sustainable and to reduce our carbon footprint.”

Turning his attention to the upcoming Interplas event, Stephen claims that he’s looking forward to attending and hearing the latest thoughts on various aspects of the industry from leading experts. He added:

“Interplas UK is the first in-person event that we will have attended in well over a year, so to say that we’re excited about it may well be an understatement.

“We’re particularly looking forward to the Sustainability Stage, which is a new addition to the exhibition this year. We’re keen to hear the thoughts of industry experts on how the plastics sector can become even more sustainable.”

Donite Plastics will be exhibiting at Stand B31 at Interplas. For more information on the services the company provides, visit www.donite.com.

Donite Plastics

+44 (0)28 9263 9995

Website

Email