Problem Solving Solutions from Design & Automation

Solving problems for manufacturers is core to Design & Automation Solutions business. Its automation experts were recently set the challenge of designing and manufacturing a robot assembly cell, with an adhesive gasket dispenser, for a leading automotive moulding producer.

Mick Stallwood, Managing Director of Design & Automation Solutions (DAS), says:

“Our client required a new system to integrate with an existing moulding machine and robot to accurately dispense adhesive gaskets for placement on a pair of plastic mouldings – with the purpose of increasing manufacturing output.

“Based around our standard DAS1220 gasket dispenser, we provided a solution which also incorporated sprue cutters and rotating product fixtures to orientate each moulding correctly for gasket placement.”

Providing bespoke solutions for various manufacturing processes, using standard components wherever possible, is core to DAS’s strength, enabling the business to be agile to every client’s needs.

Talking through the process, Stallwood continues:

“The equipment was mounted in a mobile safety interlocked guard enclosure which allowed a vacuum pick up head, fitted to the robot, to remove two impression mouldings (left & right hand) from the tool and offer them to the various devices in turn.

“Initially, the sprue is cut from the mouldings to separate them, before each is placed on its own fixture and the sprue itself discarded into a collection bin.

“The fixtures then contra rotate to align the mouldings with the gasket orientation, and the vacuum head rotates to provide a second set of cups to pick the gasket.

“Our DAS1220 accurately feeds a gasket to the pick-up position and once the robot has gripped, the dispensing edge retracts, leaving the gasket on the vacuum head.

“The robot then places the gasket on the first moulding, adhering it to the upper face, before lifting the assembled parts from the fixture and dropping them in the appropriate collection bin. In the meantime, the DAS1220 presents another gasket before the robot returns and repeats this sequence for the second moulding.

“The contra-rotating fixtures allow a single gasket with a tag to be used, removing the need for and saving the cost of opposite hand gaskets. On completion of the sequence, the fixtures return to their original position in readiness for processing the next pair of mouldings.”

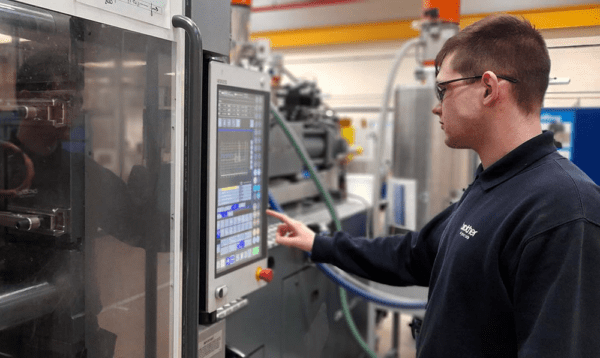

The detailed, accurate nature of the function of DAS’s work utilises Mitsubishi PLC-based control systems to operate the various devices and provide the interface signals with the robot, with an HMI used to provide messaging, manual operation functions and basic data collection. It can also be linked to a SCADA system or networked to a client’s manufacturing software system for full Industry 4.0 capability.

DAS’s modular machines are based on the many successful and innovative designs produced in over 30 years of special-purpose machinery development and manufacture.

Their flexible machines can be stand-alone or integrated and can have many additional processes incorporated to meet a client’s varied and often unique requirements.

This cost-effective route and DAS’s “Concept to Completion” service allows their clients to maximise returns on investment with benefits that can include increased productivity, improved accuracy, reduced waste and lower labour costs.

To see this machine and more from the team behind Design & Automation Solutions, watch the video below.

Alternatively, follow Design & Automation Solutions on LinkedIn or use the contact details below to see how Design & Automation Solutions can solve your automation problem.

Design & Automation Solutions

01844 355591

Website

Email