Noble Green Energy Blog // How to Cut Energy Usage Costs in Your Facility

|

Getting your Trinity Audio player ready...

|

Energy consumption is one of the biggest expenses for factories that significantly impacts both finances and the environment. A company should always strive to reduce energy consumption, but it’s critical to cut energy usage costs in your factory and boost sustainability. This goes a long way to ensuring that your customers and your clients want to work with you. In this blog, Noble Green Energy explores practical and effective ways to reduce energy usage costs in your factory while boosting sustainability. By implementing these strategies, you can save on operating expenses, contribute to environmental goals, and enhance your company’s reputation as a responsible and eco-friendly business.

Why Reducing Energy Costs Matters

Energy is a large operating expense for many industries, especially manufacturing and food production. The energy used for factories can vary significantly depending on the type of operation and the size of the factory, but heavy industries often consume far more than the smaller businesses out there.

When you choose to cut energy costs directly, you impact the bottom line, reduce the money needed for energy bills, and allow better reinvestment into the business. When you focus on reducing your energy consumption, you’ll also be contributing to sustainability goals, which ensure compliance with environmental regulations while reducing your factory’s carbon footprint.

Practical Ways to Cut Energy Usage Costs

Energy Audits & Monitoring

The best and easiest way to start cutting the energy costs in your business is to conduct an energy audit. This helps to identify areas of inefficiency and gives you some suggestions for areas of improvement. From here, you can monitor it and track your energy usage to identify any further saving opportunities.

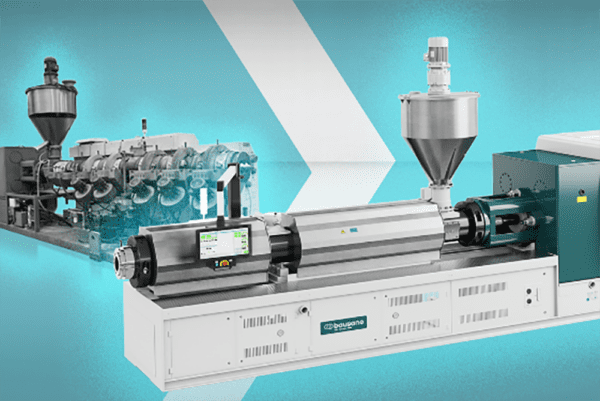

Optimise Equipment & Processes

When you invest in energy-efficient machinery and optimise your production processes, you’ll reduce your energy consumption. With regular maintenance, you’ll be able to ensure that your equipment runs efficiently, while employee training will help you prevent any further energy waste.

Upgrade Lighting & HVAC Systems

Lighting, heating, ventilation, and air conditioning systems are all key energy consumers. By switching to small thermostats and LED lighting, you’ll be able to make some substantial savings.

Energy-Efficient Building Design

If you’re renovating a new facility or building a new one, think about energy-efficient design, which could include energy-efficient windows for better insulation. This way, you’ll be able to incorporate natural ventilation to minimise the need for artificial heating and cooling. These will always include an upfront investment, but the long-term savings are worth it.

How Solar Power Can Help Reduce Energy Costs

One of the easiest and most effective ways to cut energy usage costs in your factory is by installing solar power systems. Factories with high energy consumption will benefit from solar panels that provide clean, renewable energy. It reduces reliance on grid electricity, and you can also benefit from offset installation costs.

At Noble Green Energy, we have helped many factories cut their energy costs using solar power. For example, food and beverage manufacturers are increasingly turning to solar panels for sustainability. If you’re interested in learning more about how solar energy can help your factory, get in touch with us today.

Read more news on Noble Green Energy here.

Noble Green Energy

03452 660023

Website

Email