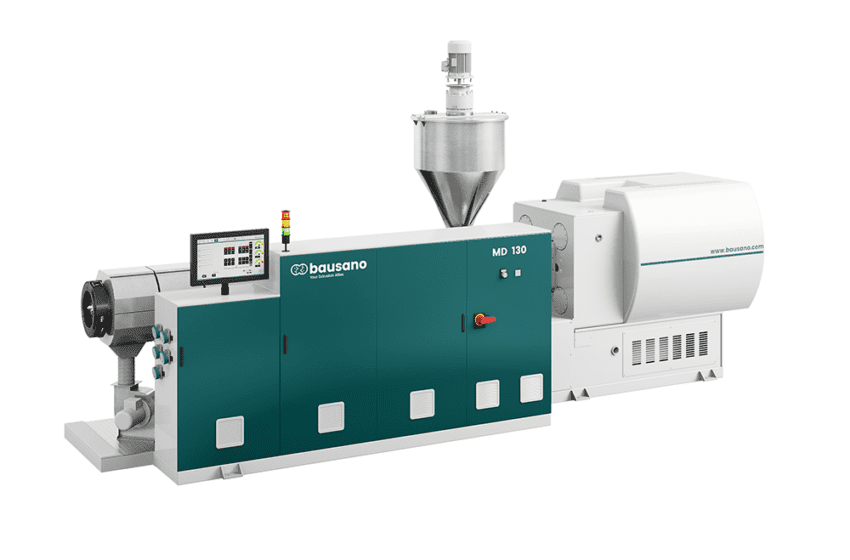

Bausano Blog // Five Reasons to Choose Counter-Rotating Twin-Screw Extruders for Your Production

|

Getting your Trinity Audio player ready...

|

Have you ever wondered which type of extruder can really make a difference in your production? The choice between counter-rotating and co-rotating twin-screw extruders is crucial, and in this blog, Bausano & Intelicare share with you why counter-rotating ones could be the ideal solution for your business.

Superior Mixing and Dispersion

Thanks to their unique configuration with screws rotating in opposite directions, counter-rotating twin-screw extruders ensure deep mixing and impeccable distribution of additives and pigments. This results in superior product quality, essential for those who want to maintain high standards in every production batch.

Energy Efficiency

Operating at low rotation speeds (10-30 rpm), counter-rotating twin-screw extruders reduce shear stress, which is ideal for heat-sensitive materials such as PVC. This characteristic not only prevents the thermal decomposition of the material but also ensures uniform gelation, fundamental for maintaining the integrity of the product.

Lower Shear Stress

Unlike co-rotating extruders that generate high shear stress, counter-rotating ones operate more gently. This is particularly advantageous for materials that require sensitive handling, preventing damage and ensuring that the material properties remain intact throughout the extrusion process.

Uniform Transport and Pressure

Counter-rotating twin-screw extruders are known for their limited but uniform solid transport. This means that the material is evenly distributed within the extruder, avoiding hot spots and improving cooling efficiency. Additionally, they operate at low pressure, reducing the risk of deformations and ensuring better control over the properties of the molten material.

Suitable for Sensitive Materials

These extruders are particularly suitable for processing thermally sensitive materials. The low rotation speed and design that avoids excessive energy input allow materials like PVC to be processed without the risk of thermal decomposition. This not only preserves the quality of the material but also extends the life of the equipment itself.

Counter-rotating twin-screw extruders represent an optimal choice for those looking to improve production quality and operational efficiency.

As the exclusive partner for Bausano in the UK and Ireland, Intelicare are at the ready to discuss how Bausano technology could benefit your business. When you invest in a Bausano extruder, you are investing in more than 100 years of experience, alongside UK based project management and aftercare.

Read more from Bausano here.

+44 (0) 7815 921 951

Website

Email