CO2 Footprint: An Opportunity for the Plastics Industry

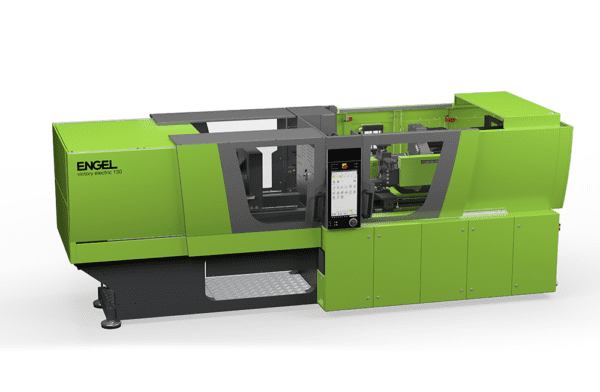

Rising energy and raw material prices see plastics processing companies face new challenges. “Reducing the CO2 footprint even faster gives companies leeway. Competitiveness and resilience are boosted,” as Dr. Gerhard Dimmler, CTO of the ENGEL Group, emphasises in the run-up to K 2022. “ENGEL is the role model when it comes to solutions that save CO2 in injection moulding. And that is precisely what we are demonstrating in Düsseldorf this October.”

“ENGEL offers a wide spectrum of mature and proven technologies and solutions that contribute towards reducing the use of energy and raw materials. The focus now is on making even more intensive use of these to substantially improve the CO2 footprint and the cost structure at the same time,” says Dimmler. From the design, sample inspection and production, through to maintenance and service, ENGEL supports its customers throughout the product life cycle and beyond. After all, reducing a company’s CO2 footprint is not a purely technical challenge. It requires close cooperation along the entire value chain, which ENGEL and other market players are actively engaged in.

Every participant in the value chain has a specific role. As an injection moulding machine manufacturer and system solutions provider, ENGEL is responsible for three areas: the overall efficiency of the injection moulding production cell, digitalisation of the injection moulding production processes, and processing technologies which support the circular economy.

Overall efficiency: It’s a question of temperature control

Conserving resources and energy has always been firmly anchored in ENGEL’s corporate philosophy. From servo-hydraulic, through hybrid, to all-electric, injection moulding machines by ENGEL are some of the most efficient on the market in their size and performance classes. “Many processors think that they have already achieved the maximum energy savings potential by using an all-electric injection moulding machine. But a precisely tuned temperature control solution helps them do far more,” as Dimmler explains. Supplying and dissipating heat often consumes more energy than the movements of the injection moulding machine in today’s production operations. This is why ENGEL has focused intensively on mould temperature control for more than ten years, offering temperature control solutions perfectly tuned for the injection moulding machines. With dynamic single-circuit closed-loop control and demand-driven control of the temperature control units, these systems solutions by ENGEL combine energy efficiency with constant temperatures and very high productivity. This makes it possible to reduce energy consumption to an extent comparable with the energy savings achieved a few years ago by switching to a state-of-the-art drive technology.

Digitalisation for consistently high product quality

iQ flow control is the smart assistance system which ENGEL specifically developed to optimise the temperature control processes. All told, the iQ product family includes nearly ten smart assistance systems and ENGEL will present another system at the K show 2022: iQ hold control. Smart assistance started ten years ago with iQ weight control, which automatically identifies fluctuations in the raw material and ambient conditions, and automatically adjusts the quality-defining process parameters individually for each cycle.

The self-optimising injection moulding machine is an essential feature in digitalising the injection moulding processes. It is all about avoiding rejects and boosting energy efficiency.

A recent study conducted by Accenture on behalf of bitkom of operations in Germany predicts that digitalisation could reduce the current CO2 emissions by up to 58 percent. At 23 percent, the manufacturing sector is responsible for a particularly large share of this.

Stretch, cover and hide for the circular economy

With its comprehensive technology know-how, ENGEL supports its customers in the processing of recycled material. “The objective of recycling plastic waste is to consume less energy than you need to produce virgin material,” Dimmler emphasises. “If you do this, the use of recycled material has an immediate positive impact on the CO2 footprint.”

ENGEL uses three keywords, stretch, cover and hide to describe the different approaches that allow the use of recycled material for a wider spectrum of applications. Stretching refers to admixing recycled material with virgin material. Plastics processing companies benefit from the great plasticising and digitalisation expertise of ENGEL here. “If you have the right screw, any injection moulding machine can process an arbitrary concentration of recycled material up to and including 100 percent recycled material,” says Dimmler. Additionally, smart assistance systems ensure that high-quality products can still be produced, even when facing major fluctuations in the raw material, which are typical of recycled plastic waste.

Covering means processing the recycled material with the use of IMD technology, such as ENGEL foilmelt or ENGEL clearmelt, along with a decorative foil or cover. And hiding means embedding recycled material in virgin material in a sandwich process, as enabled by the ENGEL skinmelt and coinjection technologies.

“Our objective is to replace the downcycling of products, which is still prevalent today, with recycling or even upcycling,” says Dimmler. “This is what drives our development work forward. ENGEL technologies make recycled material usable, even for sophisticated products.”

Information transparency through networking

The upcycling target is also supported by close cooperation among the companies along the value chain. From producing raw material, through processing to recycling and even further towards trade and the consumer, the market players are networking on horizontal platforms in order to exchange information and data. For example, the material, manufacturer and manufacturing process can be identified by means of a digital watermark on the packaging. This data is available to all participants and users of the horizontal platform. This enables more targeted sorting of plastic waste, resulting in single grade, high-quality recycling.

The R-Cycle initiative, which ENGEL joined in the spring of 2022, pursues precisely this goal. Thanks to digital product passports, R-Cycle has created the basis for a premium recycling process where information relevant to recycling is automatically recorded as early as in the manufacture of the product. “The precondition for closing material cycles is transparency of information across the entire value chain, an information cycle, so to speak,” as Dimmler emphasises. “You can only ensure the desired product properties if you know what you are processing.”

The circular economy is based on the interplay of all market players. For the process chain to work seamlessly, however, it is also important for each step in the overall process to be cost effective. “There can be no ecology without economy“, Gerhard Dimmler is convinced. “This is the point where the circle closes in order to optimise energy consumption, CO2 footprint and, in turn, the cost structure. The plastics industry needs to act quickly to leverage the opportunities that innovative technologies present.”

Read more news from ENGEL here.

ENGEL

+44 (0) 1926 335000

Website

Email