Cleanroom Classifications: What You Need to Know

Cleanrooms are an essential part of a safe medical manufacturing process. But how clean can a cleanroom be? The environmental control of a cleanroom depends on various factors, explained by Europlaz Technologies in this blog article.

Cleanrooms are an essential part of a safe medical manufacturing process. They provide a controlled environment which limits pollutants and other environmental aspects to reduce device contamination levels.

But how clean can a cleanroom be? The environmental control of a cleanroom depends on various factors, making it important to understand the different types of cleanroom classifications.

What is Cleanroom Classification?

As cleanrooms must be tailored specifically for individual manufacturing needs, they are designed in different sizes and shapes, and most importantly, levels of cleanliness, which are all used for different purposes.

ISO 14644-1:2015 is an international standard of quality control, which determines the cleanroom classification of air cleanliness in terms of the concentration of airborne particles in cleanrooms. The classification that is given to a cleanroom determines how many times the air must be filtered.

This cleanroom classification system measures the number of particulates at a specific size (0.1 micron – 5 micron) present in the cleanroom per cubic metre of air. The basis of cleanroom standards is the micrometre, which abbreviates to micron (µm), which is the size of the particles to be filtered.

The Different Cleanroom Classifications

Cleanroom classifications are based on ISO classes which span from ISO 9 to ISO 1. ISO 1 is the cleanest, and although ISO class 9 is significantly cleaner than a normal room, it requires the least amount of air filtration of all the classes.

A general rule of thumb in cleanroom classifications is that the air particles need to be filtered twice as much as the classification above it.

For example, an ISO class 7 accredited cleanroom must include the minimum:

- 60-90 air changes per hour

- 352,000 particles per cubic metre (PPC) at 0.5μm

- HEPA filters which are 99.997% efficient at 0.3 microns

- A separate changing room

- Testing every six months

As a successful Medical Device Manufacturer, we have six ISO class 7 cleanrooms at Europlaz, which are all compliant with ISO 14644. Our cleanrooms are specifically designed for processing class I and class II medical devices, equipment and pharmaceutical products.

To maintain the high standards of our cleanrooms, we use routine air pressure, micro-organism and airborne particulate monitoring.

What Products Can You Manufacture in a Cleanroom?

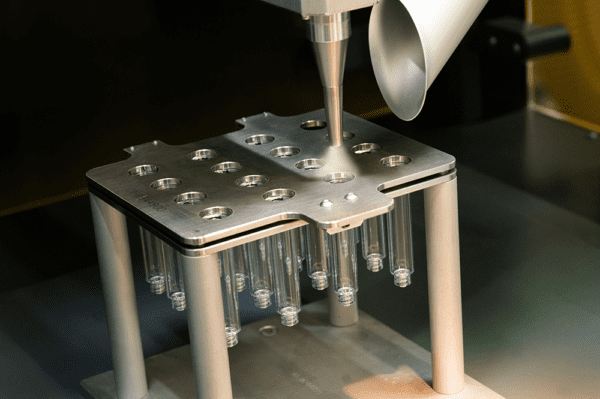

We develop many different medical devices within our state-of-the-art cleanrooms. Our injection moulding machines, including our Krauss Maffei: 350T (the largest injection moulding machine in a cleanroom in Europe), allow us to produce devices exactly to our clients’ requirements.

From thermal moulding to adhesive and UV bonding, we use various solutions within our cleanrooms to meet manufacturing requirements. A full list of our cleanroom solutions can be accessed here.

Here at Europlaz, we have the facilities and knowledge to help bring your vision to life, from the research and design phase all the way to the prototyping, production and packaging of your final product.

If you need state-of-the-art cleanrooms alongside an expert team of medical manufacturers with over 40 years’ experience for your next project, get in touch with us today.

Europlaz Technologies

+44 (0)1621 773 471

Website

Email