Broadway Blog // Why Colour Matching in Plastics is Critical to Maintaining Brand Integrity

|

Getting your Trinity Audio player ready...

|

In today’s crowded marketplace, colour plays a pivotal role in brand and product recognition. From the iconic purple of a chocolate bar to the specific blue of a tech gadget, colour isn’t just an aesthetic choice – it’s a powerful brand asset. Consistently accurate colour reproduction is crucial for upholding brand integrity. For consumer goods companies, it’s essential to partner with a supplier capable of achieving precise colour matching in plastic products and packaging. In this blog, Broadway Colours explores why colour matching in plastics is vital for upholding your brand identity and how to ensure precision and reliability in every custom colour.

Custom Colours Differentiate Your Brand

In a competitive market, standing out is non-negotiable. Your unique colours not only differentiate your brand but also leave a lasting impression on consumers. Your colour communicates your brand’s values, personality, and quality. Broadway specialises in developing custom colourants for plastics, ensuring that your product aligns seamlessly with other consumer touchpoints.

How we help brands stand out

With over 27 years of experience, Broadway has developed more than 56,000 custom colour matches for industry sectors such as cosmetics, personal care, and food and beverage. Our skilled colourists collaborate closely with brands to create unique colour formulations that enhance brand identity.

Whether you need a bold, attention-grabbing colour or a subtle tone to communicate your brand’s sophistication, you can rely on our free colour matching service. Our expert colourists will provide the solution you desire with speed and accuracy. We’ll develop your new custom colour and send sample plaques for approval, typically within just 3-5 working days, all free of charge.

Colour Accuracy Builds Consumer Trust

When consumers purchase a product, they expect the colour to match what they saw online, in ads, or on store shelves. Inaccurate colours can lead to disappointment, undermining consumer trust – particularly for products sold online where consumers make purchasing decisions based on visuals alone.

Broadway’s commitment to accuracy:

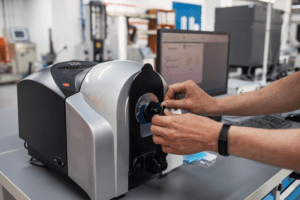

At Broadway, we use a combination of old heads and new technology to ensure that your brand colours are accurately represented in your plastic product or packaging. Our expert colourists consider factors like polymer type, processing conditions, and lighting environments to ensure the colours you envision are the colours your customers see. We maintain tight tolerances of just one Delta-E, analysed with the use of spectrophotometers as well experienced eyes.

Leading moulders across the UK and Europe utilise Broadway’s high-quality colour masterbatches and our materials are specified by several multinational consumer goods companies.

Strengthens Brand Recognition

A brand’s colour is one of the first elements consumers recognise, and it can have a lasting impact on their perceptions. Consistent use of colour across a product range reinforces brand recognition and builds trust. Whether it’s packaging, components, or promotional items, colour deviation will undermine trust in your brand.

How we ensure consistency:

At Broadway, we understand that colour consistency is key. Our advanced colour-matching techniques allow us to replicate your brand colours with precision, even across different types of plastics. This can be especially important where a cap or closure is made using a different polymer to the jar or bottle on which it sits. Broadway can provide custom formulations for each element of your packaging, achieving a uniform finish.

We also offer a range of performance-enhancing additives which we call + performance. Our UV protection packages reduce the degradation of polymers used in outdoor applications, this helps to preserve colours. Some additives can cause a slight colour change, but our colourists will make adjustments to colour formulations to compensate for this and ensure consistency.

With bespoke internal technology platforms and robust QC procedures, we ensure accurate repeatability of approved colours. Every colour mix is QC checked against a master standard, eliminating the potential for batch variances or colour deviation. Our quality management has been certified to the ISO 9001:2015 standard.

Once customised materials leave our factory, it’s important that they process effectively, to maintain consistency throughout your production run. Our custom formulations are polymer-specific, this means they’re each designed for optimum performance with the specific type of plastic used in your moulding. We also include processing additives to facilitate even colour dispersion. Our knowledgeable technical team are on hand to offer support and advice to plastic moulders as they need it.

Balancing Sustainability with Brand Consistency

Responsible consumers are becoming increasing mindful of the environmental impact of their purchasing decisions and many brands are rightly seeking to make more sustainable material choices. In the case of plastics, this often means increasing their use of PCR (post-consumer recycled) materials. This solution also offers commercial benefit, with plastic packaging now requiring at least 30% PCR content to avoid The UK Plastic Packaging Tax of £217.85 per tonne.

Whilst adopting high levels of PCR is good for reducing taxes and, most importantly, environmental impact, it can cause headaches for plastic colourists. As you might expect, PCR lacks the clarity of virgin polymer. The inherent tint within the polymer will influence the final colour of your moulding and can impede the ability to achieve bright colours or lighter tints. The other issue is that PCR suffers from batch variances, so even if your colour masterbatch formulation is consistent, your end mouldings may not be.

How we combine sustainability with brand integrity:

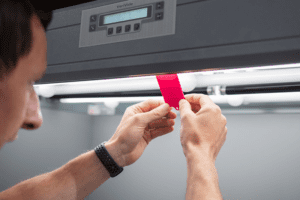

Broadway has many years of experience in colouring recycled plastics. We often host brand owners in our on-site colour matching suite. This facility allows our customers to visit us to approve their new colour samples. This is a great option when moulding with high levels of PCR. The customer can bring a sample batch of their specific moulding material so colour formulation adjustments can be applied, to counteract the colour deviance caused by their specific base polymer.

New sample plaques can be reviewed immediately against previous plaques, or a moulded product, to check the formulation adjustment accurately pulls the brand colour back in line with the previous standard. If the customer’s PCR grade changes at a later date, then this process can simply be revisited as required.

On-site matching also speeds up the colour approval process, saving time on product development. No longer does the brand owner have to wait for the colour house to post sample plaques to a plastic moulder to review and pass on. This process allows for instant review of plaques, hot off Broadway’s injection moulding machines.

If colour adjustments are needed then this can be discussed immediately and in person with the colourist. A range of new colours can be approved within a matter of hours, rather than days or weeks. This solution helps customers meet their sustainability targets, without delays or significant compromises on their brand colour.

Conclusion

Colour is more than just a final touch – it’s a vital element of your brand’s identity. Achieving precise and consistent colour matching is essential for building brand recognition and maintaining shelf appeal. At Broadway, we pride ourselves on delivering a precise, efficient and reliable colour matching service, as well as high-quality, consistent colour masterbatches which process exactly as intended.

If you’re looking for a partner who understands the importance of colour in brand identity, contact us today to discuss your needs or to take advantage of our free colour matching service. We also offer a range of special effects, customisable to your specific colour requirements.

Read more news from Broadway here.

Broadway

+44(0)1986 875 100

Website

Email