Borough Chrome Growing its Injection Moulding Machine List

|

Getting your Trinity Audio player ready...

|

Borough Chrome, as the name suggests, is renowned worldwide for its ability to apply a bright chrome plate to the surface of plastic components, ensuring they match the durability of the metal parts they are designed to replace.

Since perfecting the technique in the 1970s, Borough Chrome’s clients have sent a huge variety of plastic components of all shapes and sizes to be chrome-plated at their Leigh-on-Sea facility. Given their experience, Borough Chrome advised the manufacturers of the plastic components on how to design specifically for chrome plating, which required a different approach.

Recognising the difficulty of achieving a consistently high-quality finish that can be introduced to the plating process when parts are not designed for the purpose, Borough Chrome took the important decision to invest in their injection moulding machines.

Building Their Mould Shop

In May 2002, Borough Chrome’s first machine, a Sandretto (acquired by ROMI in 2008) UK3020, was installed and commissioned, since which time it has recorded almost 100,000 hours of consistent injection moulding service.

This machine was the perfect starting point for their mould shop, with its 130-ton clamp pressure and 410 x 410 mm space between the tie-bars, allowing Borough Chrome to successfully mould and plate a range of smaller ABS components.

Now able to ensure each component was designed to be chrome plated and with control over the moulding process, the quality of the completed chrome-plated parts reached the heights for which Borough Chrome is renowned today.

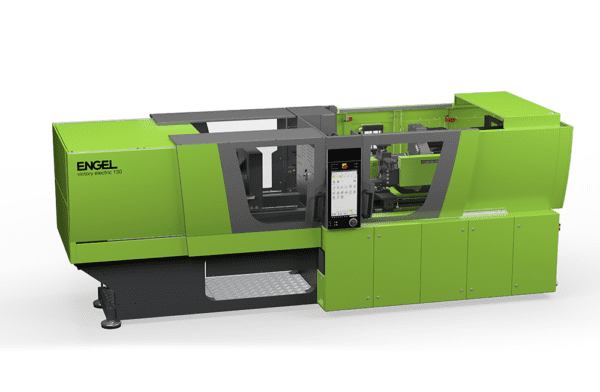

Recognising the strong position this total control of the process gave them, Borough Chrome has continued to invest in their mould shop, with machines from Sandretto, ROMI, and Engel quickly enlarging their growing plant inventory, which currently stands at:

- ROMI EN70

- ROMI EN220

- ROMI EN300

- Sandretto 130s

- Sandretto 230s

- Sandretto 230hp

- Engel 300v

- Engel 300vp

- Engel 400c

Over time, to suit specific contracts across a range of sectors, from automotive to washroom, Borough Chrome has specified machines that ensure they can achieve a wide range of component sizes, which are generally limited by the distance between the tie-bars.

The size of components they can mould changed significantly with the arrival of the Engel 400C, a tie-bar-less injection moulding machine that ensures a particularly even clamping force distribution across larger tools.

Without the tie-bars restricting access to the platen, Borough Chrome can accommodate tools capable of injection moulding components as large as the two-part chrome front grill cover moulding trim or the single-piece grill surround for MINI, both of which measure almost a metre in length.

Importantly, this particular technically advanced Engel was also their first ‘2-shot’ machine. This technology allows Borough Chrome to provide plastic components with complex ‘B’ surfaces, that only have chrome selectively applied, to ensure parts that need to flex such as tabs, still can.

At the time of writing, their machines have collectively recorded almost 500,000 operating hours or an incredible 30 million minutes. Given a minute is closer to the cycle time of most of the components they mould, this gives you some idea of the scale of their injection moulding operation.

When you consider Borough Chrome still chrome plates plastic components supplied to them and some of the components they mould are in pairs in the tool, you start to get an impression of the overall scale of Borough Chrome and their impact on the industry.

If you are designing injection moulded components for a project, whether they are chrome-plated or not, Borough Chrome has the expertise and the experience to help you get the best results, whilst shortening your supply chain thanks to their UK-based facility. Please get in touch, they love to discuss moulding and chrome plating.

Read more news from Borough Chrome here.

+44 (0) 1702 425425

Website

Email