BMB Invests in the Future: 4th Production Unit is Ready

The major Italian injection moulding machine manufacturer has confirmed its commitment to the future growth of the plastics industry, with the construction of a new production department, the fourth, adjacent to its Brescia headquarters.

Number 4 – State of the art Factory

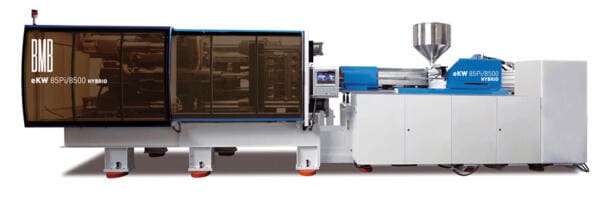

The new state of the art smart factory will allow BMB to operate more efficiently and meet the increasing demand from new and existing customers and also enable the existing range – 100tonnes clamp force to 3,500 tonnes clamp force—to be extended to 4,500 tonnes clamp force, two of which are in the final assembly stages in the new production unit.

Many of the major BMB components are made in house or supplied within a small radius of Headquarters, with all proprietary components sourced in Europe e.g. Germany and Switzerland. All raw materials for platens, bases etc. are made from top quality Italian steel.

With the recent events, the world is now adapting to a new type of smart working, Industry 4.0 technology within BMB opens the door to new possibilities for process control and machine smart control. Since 2001 BMB has supplied teleservice support for all customers via remote assistance which is free of charge for life.

The eKW Full Electric range now increases to 1300 Tonne clamping force, and the eKW hybrid range to 2800 Tonnes clamp force Fully Electric clamp system.

The new production structure extends over 6400 square meters and will be used for the assembly of medium and large injection moulding machines. For this purpose, it is equipped with four cranes with a capacity of 100 tonnes and an automated painting department.

BMB – your partner ready for the future!

BMB Plastics Machinery Limited

+44 (0) 188 958 4483

Website

Email