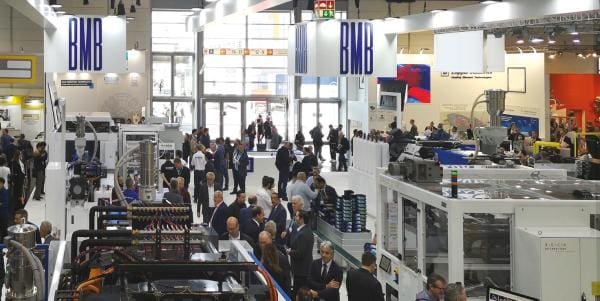

BMB Focuses on Speed, Thin-Walled Production and Energy Saving at K 2022

After the pandemic, a time full of great uncertainty led to reduced investments in research and development. This, in conjunction with the energy price increase, is strongly affecting our lives, thus leading BMB to focus on energy savings for K 2022.

BMB’s goal is to aim at high productivity but give new breathing space to the packaging manufacturers.

With four production cells running during the exhibition, BMB will convey the message of excellent reliability even for the most demanding applications, an example of which will be a cycle time of 2.3 s but with a particular focus on energy consumption reduction.

The benefits are guaranteed if consumption can be contained with these fast cycles.

The machines will also be equipped with a new CNC control where the operator interface is improved thanks to a larger screen and the integration of some new digital functions.

eKW28Pi/1300+330 Full Electric

The application concerns the production of two-colour flip-tops for cosmetics from a 16- cavity mould. The 280 tonnes complete electric machine exhibited will showcase high precision moulding; the two-colour or two-component injection moulding machines are increasingly requested for various sectors and needs, in case of an item made combining different weights and materials

eKW20Pi/700 full electric (c/o stand Enelkon 12/A43)

This application is perhaps one of the best examples of productivity with low energy consumption. All this is possible thanks to a perfect balance between machine, mould, automation, and ancilliary accessories. The eKW20Pi/700 full electric machine model will be exhibited at our partner Enelkon’s stand (Hall 12/A43). Enelkon will demonstrate the entire cell, consisting of an IML automation system equipped with ten cameras and a stacking system to place the products in cardboard boxes.

eKW85HP/12500 Hybrid

This 850 tonnes high-performance machine is ideal for packaging applications with products with a ‘deep draw’ design, such as buckets, home containers, hospitals, and other waste material containers. This machine is characterised by a very high injection speed, which is necessary for the correct production of thin-walled parts. Thanks to the direct electric drives and roller recirculation screws on opening and closing, extraction, and plasticisation, it is possible to obtain energy consumption similar to that of a fully electric press, with the advantage of an injection speed of about two m/s.

eKW70HP/3450 WP Hybrid

The application involves moulding thin-walled round containers with wrap-around and bottom IML. The production of 8 containers with two labels each, monitored by cameras and then packaged. This system is a customized production cell that will be shipped to the end user after the fair.

Thanks to HolyGrail 2.0 technology, the label can show the content details through a smartphone. This important feature allows the transfer of multiple pieces of information that may relate to production, expiry date, or recycling instructions. The cameras used in the recycling plants can collect information on the material and, therefore, direct and separate the different types of plastic for an accurate recycling process.

For over 50 years, BMB has pursued uncompromising product quality. This philosophy that has seen BMB remain anchored to strategic choices, linked to direct drives with recirculating roller screws, to the best platens parallelism found on the market, and to many other peculiarities, has significantly contributed to giving a high-quality identity brand quality.

Centralised oil lubrication, liquid cooling on all drives, and braking energy recovery have always made the difference in terms of performance, reliability, and energy saving.

Now more than ever, the choices of long and careful research are proving to be fundamental for us and, above all, our customers.

Read more news from BMB Plastics Machinery here.

BMB Plastics Machinery Limited

+44 (0) 7551 312685

Website

Email