3 Reasons to Think Twice Before Purchasing Your Next Mould

Traditional manufacturing methods such as injection moulding have been around for decades and remain a solid option for most projects once the market demand and product requirements have all been validated. However, there are times when considering other options can provide some major benefits.

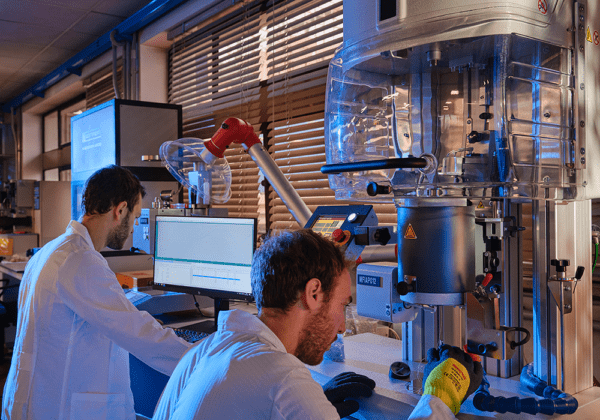

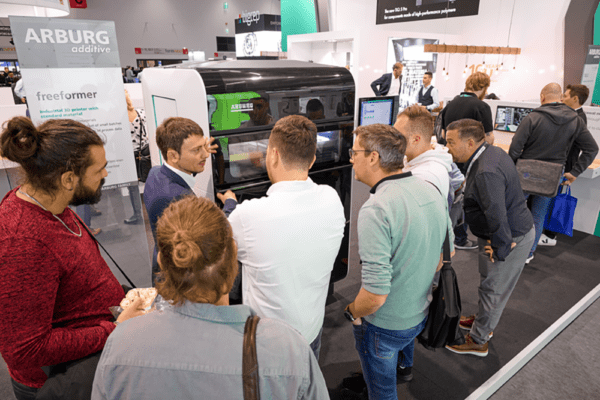

New developments in 3D printing are lowering the price per part, and this should pique the attention of decision makers to consider it as a viable option for production runs of up to 10,000 parts. Here are just some of the key benefits –

1) It can be (a lot) more cost-effective.

3D Printing has zero setup costs! Unlike injection moulding, the technology doesn’t require a mould tool to start producing parts. Projects can get going a lot faster and the cost is determined on a per-part basis

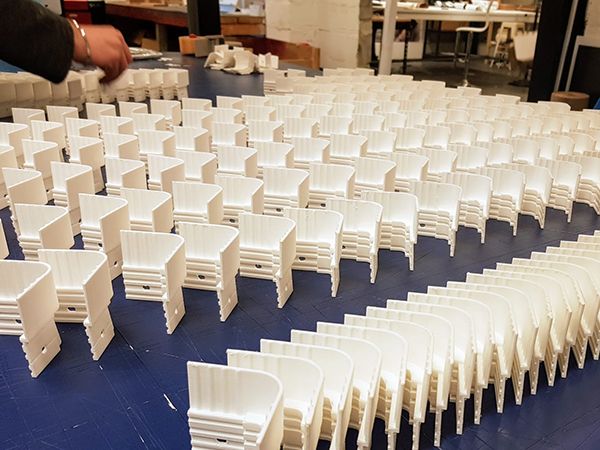

When looking to get a few hundred or thousand parts made, the cost of the mould can end up being prohibitive to the project. At this stage, 3D printing can bring a refreshing air of feasibility on those riskier projects, enabling more projects to flourish!

2) Change your design on-the-fly!

If for any reason your design needs tweaking – no problem! You can easily update your CAD file and receive updated parts within days. No need to dish out £10,000’s on moulds. This design flexibility allows you to continue improving your design whilst continuing to sell units. What’s more, you can also change material and colour anytime, whereas with injection moulding you will often require a new mould to compensate for the varying shrinkage ratio when the part is made.

3) Rocket to Market, Faster…

Getting a mould made in China to produce 2,000 parts then waiting 6 weeks for your parts to arrive? Now you could save both money and time getting your parts 3D printed here in the UK.

Whatever production method you choose to use, it’s always a good idea to scan the options before committing large sums of money. At Prodpoint, we’re used to working with designers and engineers to achieve optimal results on their project. We can provide samples of your designs at low-cost for your review, and even if 3D printing isn’t suitable for your project, we’ll happily point you in the right direction.

PRODPOINT Ltd

+44 (0) 1394 822025

Website

Email