Bausano Extruders Come Out on Top for PlastChem

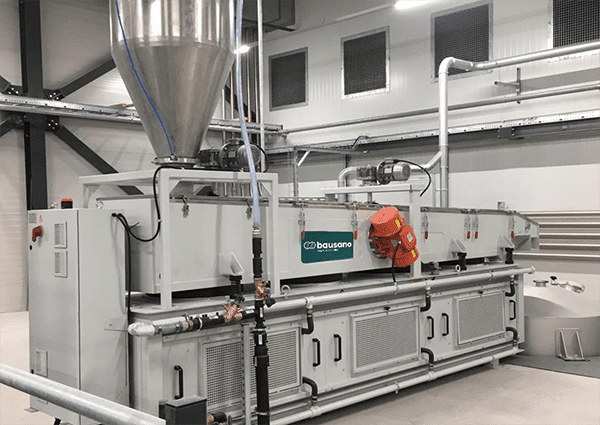

PlastChem, which already operates an MD 158 Nextmover granulation line and the model MD 66 Nextmover for its laboratory tests, has chosen Bausano’s extrusion lines once again for the most advanced PVC factory in Europe which has recently opened.

PlastChem B.V., a Dutch company that specialises in producing PVC granules for extrusion and injection moulding, has opened the most advanced PVC production plant of all Europe in Hardenberg, the Netherlands, and once again relies on Bausano extruders. PlastChem has renewed its partnership with extruder manufacturer Bausano for two additional lines at the new site, which will ensure a high output per kg/h, consistent quality and reduced energy consumption.

PlastChem is an internationally successful company offering proven know-how in plastics applications, developed over more than 30 years of activity. Its strength lies in its constant ability to renew and enhance its processes, consistently guaranteeing perfect compounds that meet the customer needs as for shape and specifications, for a total of tens of thousands of tonnes of extruded PVC granules per year. With that in mind, Bausano, a leading international player in designing and manufacturing customised extrusion lines to process plastic materials, stands out as the only partner that can address the customisation requirements to treat PlastChem exclusive blends. In particular, its expertise has made a difference in the design of high-performance machines with high energy efficiency and reduced carbon footprint.

More specifically, Bausano achieves these milestones thanks to the technological innovations featured in the new MD Nextmover models. Such innovations include the Smart Energy System, the electromagnetic induction technology designed by Bausano and chosen by PlastChem for its lines, which guarantees faster and more homogeneous heating of the barrel and the material processed, resulting in a 30-35% decrease in consumption. Another plus is the Digital Extruder Control 4.0: an innovative system, which monitors all the plant production parameters and energy efficiency, to meet the Industry 4.0 latest vertical integration requirements.

“Bausano is an invaluable partner for the growth of our company, both in terms of its high added-value consultancy and its continued support and problem-solving speed,” says Tom Baveld, Chief Operating Officer of PlastChem. “For this reason, we have undertaken a long-term collaboration involving both companies working together to find the best solution, enabling to adopt the best practices and the most advanced and efficient technologies to increase its competitiveness in the market,” he then adds.

“A clear evidence of this is the expansion of our equipment, with two additional granulation lines, on the opening of our new production site,” Tom concludes.

“We would like to thank PlastChem for their continued confidence in our solutions, which are designed to increase the company’s performance and reduce its impact on the environment,” says Bausano Technical Sales Manager Alfeo Bonato. “Such a result was made possible thanks to the synergistic collaboration of our technicians with the client’s team, a distinctive element of the organisational model adopted by Bausano and based on complete customer satisfaction.”

Bausano

+44 (0)1777 248777

Website

Email