Arburg to Showcase Numerous Innovative Technologies at Interplas 2021

Arburg‘s digitally networked, electric Allrounder with a ground-breaking Gestica-control system will take pride of place at its Interplas stand. The Arburg host computer system ALS and the arburgXworld customer portal will also be on show at the exhibition.

The injection moulding machine manufacturer Arburg can be found on Stand H4 in Hall 4 at Interplas from 28-30 September.

Colin Tirel, Arburg UK’s Managing Director, said:

“After a break of four years since the last Interplas, we are very much looking forward to having fact to face contact with customers and any interested parties in person once again. Business is better than ever and the market in the UK and Ireland overall is booming, too.

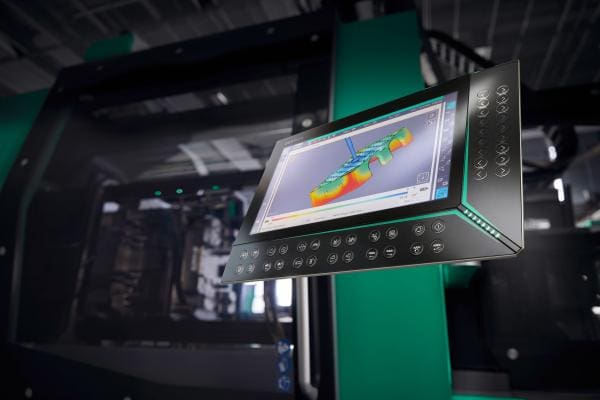

“At the trade fair, we will be exhibiting an Allrounder with a Gestica-control system for the first time in our market. This energy-efficient production cell will also bundle together numerous innovative technologies, all of which make injection moulding more efficient and convenient. For that reason alone, a visit to our trade fair stand will certainly be well worthwhile.”

Smart turnkey system

The smart turnkey system manufactures plastic cups fully automatically, which can be sorted by type by means of a digital product passport. The application sets new plastics processing standards in terms of digitalisation, automation and the circular economy.

The heart of our turnkey system is an electric Allrounder 370 A with a clamping force of 600 kN, a single hot runner mould by Haidlmair and the new vertical robotic system Multilift V 20 with a 20kg load in a transverse design. The machine is also equipped with an IIoT gateway as standard. In addition, the system is connected to the Arburg Turnkey Control Module (ATCM) Scada system, which amalgamates all the relevant process and quality data for each specific part. A cup is manufactured from PP, then printed with a QR code according to the injection moulding process. This enables separation by type after use.

Digital product passport ensures correct sorting

As a result, Arburg – as an exclusive engineering partner in the R-Cycle initiative – demonstrates with cup production too how high-quality recyclate can be recovered from plastic waste after products have been used, thereby closing the recycling loop. The pivotal element of R-Cycle is a database that contains all the information about the materials used. As a result, every plastic product is assigned a digital product passport. As early as the injection moulding stage, data relating to aspects such as raw materials and colouring agents are transmitted. The code is then read, making separation by type possible.

Intelligent assistance functions

The exhibit is equipped with intelligent assistance systems. This enables the aXw Control FillAssist to run filling simulations directly on the Gestica-control system screen. The tool uses the pre-created simulation model and part geometry to make the changeover and set-up more efficient. The three other control systems, “aXw Control ScrewPilot”, “aXw Control PressurePilot” and “aXw Control ReferencePilot”, ensure the injection is adaptive and regulated. These are control strategies that build on each other and offer solutions for key quality requirements such as constant shot weights and uniform mould filling.

arburgXworld: News about the customer portal and digitalisation

Visitors can learn how to digitalise their production at two terminals with the “arburgXworld” customer portal and the Arburg host computer system ALS. Through the connection to ALS, production data can be recorded and analysed in real-time, significantly increasing production efficiency and transparency. With its free-of-charge basic version and numerous apps and configuration levels, “arburgXworld” offers customers comprehensive digital support and access to a wealth of information and Arburg know-how. Key features include an overview of the machine fleet (MachineCenter) and online spare parts orders (Shop). Arburg continually updates its customer portal with new digital services, which creates added value and makes everyday injection moulding easier. This includes the “AnalyticsCenter” for documenting mould sampling, tests, and injection moulding processes.

Click here to register for Interplas. Be sure to visit Arburg on Stand H4 in Hall 4 during the three-day event.

ARBURG

(0) 19 26 45 70 00

Website

Email