Ampacet’s GASTOP-Flex™ Boosts Barrier Performance While Supporting Packaging Circularity

|

Getting your Trinity Audio player ready...

|

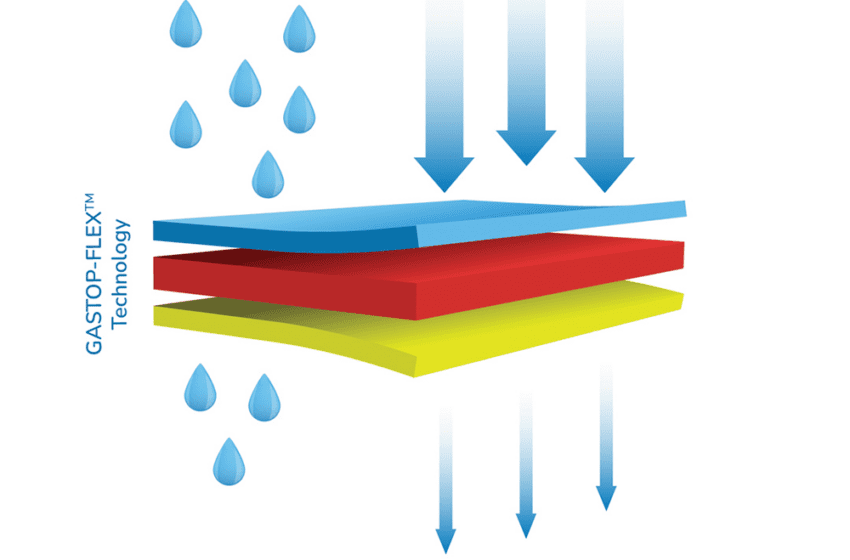

Ampacet, a global masterbatch leader committed to advancing sustainable solutions, the company’s GASTOP-Flex™ technology is a solution for enhancing gas barrier performance in polyolefin-based flexible packaging. GASTOP-Flex™ supports packaging producers in reducing plastic material usage and improving compatibility with recycling systems, in line with circular economy goals.

Ampacet’s GASTOP-Flex™ technology addresses the growing need to reduce plastic packaging waste and improve circularity across the packaging value chain.

Gas barrier properties of polyolefin flexible packaging are typically increased with the use of thicker packaging, co-extruded barrier material or multi-material laminates. Thicker packaging, however, is not optimum in terms of packaging material resource efficiency, especially at times when brand owners pledge to reduce the amount of plastic used in their packaging. Multi-material coextruded or laminated packaging is often not fully compatible with packaging waste recyclability requirements.

Added to polyolefins, GASTOP-FlexTM masterbatches boost the inherent packaging barrier performances with a reduction of both oxygen and water vapour transmission rates by up to 60% of their initial values.

GASTOP-FlexTM technology enables down-gauging of general-purpose packaging used for dry food (e.g. bag-in-box cereal liners) preserving the barrier to moisture (WVTR) and shelf-life of packed dry food. GASTOP-FlexTM also allows to achieve of high barrier packaging performances (OTR and WVTR) while keeping the EVOH content below the maximum 5% threshold specified by the most popular design guidelines for circular economy.

Adding GASTOP-FlexTM to packaging will support packaging manufacturers and brand owners to achieve their sustainability goals in reducing the quantity of plastic packaging material and waste and designing packaging with a higher compatibility with existing sorting and recycling infrastructures.

For more information on the Ampacet GASTOP-Flex product range, email marketing.europe@ampacet.com. Ampacet will be pleased to welcome you to our booth at the K show in Düsseldorf, Germany.

Read more news from Ampacet here.

Ampacet

01952 581814

Website

Email