Aluminium Tooling: Friend or Foe?

Aluminium can offer significant advantages when specified correctly but is far from a panacea and recognising its drawbacks is very important. Plunkett Associates investigate in this informative blog article.

There are many applications that require production material parts, early in the development cycle. This could be for mechanical properties, chemical resistance, temperature capability to name but a few.

The issue then becomes one of how to ‘control’ the lead time associated with the mould tooling and try to short cut both the time and cost associated with conventional production tooling.

At Plunkett Associates, we try to understand exactly what the driver behind the requirement is, so that we can tailor the solution rather than apply a one size fits all strategy.

Aluminium can offer significant advantages in this environment when specified correctly but is far from a panacea and recognising its drawbacks is very important.

Time

Most material suppliers will ship your order in 2 – 5 working days, meaning that if you do not have the material in stock, there is an immediate delay. Then there is the standard preparatory work that goes on, once the material has arrived, to get it into a state that can be used. Now on a small part, this will dwarf any machining time difference between aluminium and steel; the real time saving comes from stock holding material in a condition that is ready to take the specific mould form.

As the physical part size grows, so material lead times can extend, but so do machining times, and on larger parts, it is certainly true that aluminium offers a time advantage. Also being a softer material, it is possible to machine a lot more geometry than would be possible in steel, thus offering less process steps to the toolmaker to achieve the final form.

Surface finishes can be delivered faster as well, be that a gloss finish or a texture.

So, what does this mean? Tooling in a press, ready to mould, in under a week but that has to be qualified – depending on size and geometry!

Geometry

This can dictate the choice of tooling material.

Aluminium is a definite friend when faced with larger or simpler parts. However, it does not have the strength of steel, so features that require thin blades in the tool, lots of features with high aspect ratios or complex shut-offs, can lead to problems – or the need to insert specific features.

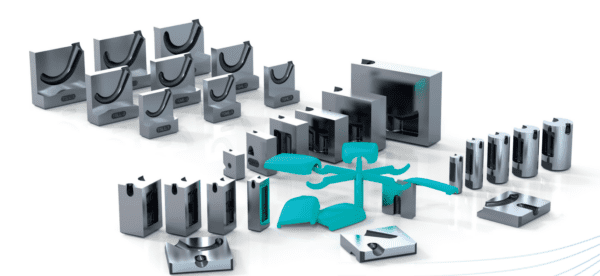

When making development tools, where we know the geometry will change, and the numbers are low, we can reap the benefits of aluminium. Using standard parts and loose inserts, we can tackle a wide variety of geometries and iterate a design through multiple variants to tune the optimum configuration, all prior to the release of production tooling.

Life

The life of an aluminium tool is dependent upon the grade of aluminium used, the material being moulded, the care and attention used when moulding and of course the part complexity as already alluded to.

The aluminium we generally use for tooling is 7000 series, this offers better hardness and stability than other grades.

The moulded material will have a bearing as you can imagine a glass loaded nylon (GFN) will wear an aluminium tool far faster than a material like polypropylene (PP). This is not to say that GFN cannot be moulded, just that it will impact tool life, especially in areas like the gate.

Texture has to be considered in this equation as well, depending on the tool/part design an aluminium tool can require re-texturing whereas this is unheard of (in our circles) for a steel tool.

Moulding

Yes, aluminium is softer than steel and hence it needs a bit more care when moulding. The most likely causes of damage come from a stuck part being removed too ‘vigorously’, a part failing to clear or a shutoff being bruised when moulding.

Both these can be addressed and are seen more often when an aluminium tool is put into a predominantly steel tool shop.

When should I consider using an aluminium tool?

The obvious situations are in development, or as a bridge to production. (Hence the term bridge tooling)

However, aluminium will take you a lot further. Many new projects struggle to predict early sales and hence applicable investment. Aluminium bridge tooling will allow a market to be quantified before spending larger sums on production tooling and having the confidence to specify multi-cavity tooling.

We even had one client who purchased an aluminium tool on their R and D budget that was so successful they were able to ‘sell’ it to production. That must have raised some interesting accounting questions!

In our book, aluminium tooling is a definite friend that we would not want to be without.

Optimising tooling solutions

We have already established a track record of optimising tooling solutions to meet specific requirements with regards to quantities, geometries and speed.

We believe the added support we offer our clients with their tooling and moulding requirements is second to none. Our specialist design support and the variety and flexibility of tooling and moulding options we are able to offer is key to successful parts and a project delivered on time and in budget.

If you have a requirement for prototype tooling or moulding and you would like to take advantage of our added value services, please contact us now for a personalised quote.

Plunkett Associates

+44 (0)1452 386608

Website

Email