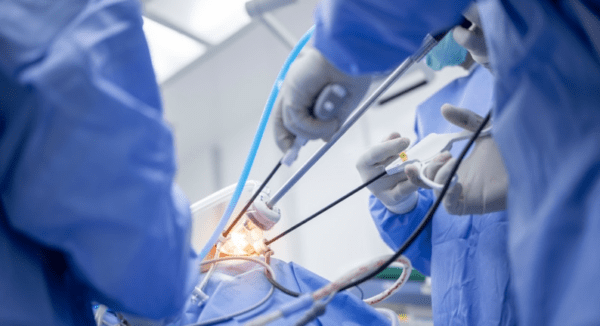

Alliance Tooling Revolutionising Keyhole Surgery with Sustainable Innovation

|

Getting your Trinity Audio player ready...

|

A leading medical device manufacturer sought the expertise of Alliance Tooling, a premier British plastic injection mould toolmaker, to embark on an ambitious project. The goal was to develop a new polycarbonate cap for an optical trocar device used in keyhole surgery. This innovative product aimed to be the first reusable component in the market, indicating a significant leap towards sustainability in medical procedures.

Client Challenge

The project presented several challenges, primarily ensuring the complex cap design was optimised for mass manufacturing through plastic injection moulding. Achieving this required a delicate balance between functionality, aesthetic appeal, and production efficiency.

Alliance Tooling Approach

Alliance Tooling is committed to delivering excellence through collaboration and technical innovation. Understanding the critical nature of this project, their team of injection mould tool designers engaged in regular, intensive meetings with their clients. This collaborative approach allowed us to understand the product requirements and the challenges it presented thoroughly.

To address these challenges, they embarked on a rigorous process of mould design optimisation. Their focus was refining the cap’s wall thicknesses and drafts to ensure manufacturability without compromising its aesthetic appeal to the end user. Through these efforts, they successfully navigated the complexities of the design, ensuring the cap could be moulded efficiently on a mass scale.

Project Highlights

The project was marked by several vital achievements that underscored Alliance Tooling’s commitment to innovation and sustainability:

- Annual Plastic Waste Reduction: By introducing this reusable cap, they estimated a significant reduction of 1 ton of plastic waste annually. This achievement supports environmental sustainability and represents a milestone in the medical industry’s efforts to minimise material waste.

- Optimised Tool Design for Mass Manufacturing: Leveraging their extensive experience in injection mould toolmaking, Alliance Tooling successfully optimised the cap’s design for mass production. This optimisation process was critical in ensuring the product could be injection moulded efficiently without sacrificing quality or functionality.

- Innovative Manufacturing Techniques: The project utilised fully hardened steel inserts and a direct 8 drop valve gate runner system. These advanced manufacturing techniques contributed to the high quality and durability of the final product.

- Enhanced Product Finishing: The cap featured a textured finish on the A side and a polished finish on the B side, demonstrating their ability to achieve high aesthetic standards alongside functional requirements.

- Efficient Ejection System: Incorporating a stripper plate ejection system exemplified their commitment to manufacturing efficiency, ensuring smooth and reliable production processes.

Conclusion

The successful completion of the optical trocar device cap project is a testament to Alliance Tooling’s expertise in plastic injection mould tooling, specifically within the medical sector. This project not only delivered a first-of-its-kind product to the market but also set new standards for environmental responsibility in the medical device industry.

Alliance Tooling is proud to have partnered with its client in this groundbreaking project, demonstrating its ability to tackle complex challenges through innovation, collaboration, and quality.

Read more news from Alliance Tooling.

+44(0)1162 750 584

Website

Email