Pultrex and KraussMaffei: A Perfect Alliance in Pultrusion

Pultrex is a market leader in pultrusion, with over 40 years of experience in composite machinery manufacture and profile production. One year on from its acquisition by KraussMaffei, we catch up with the Essex-based manufacturer.

Philipp Zimmermann, Head of Sales Reaction Process Machinery at KraussMaffei (pictured, right), and Ian Raymant, Managing Director Pultrex (pictured, left), discuss the new common strengths and the great potential within the pultrusion market.

The new alliance offers great synergies to tackle the increasing potentials within the pultrusion markets – with new materials, technologies, and applications. What is the experience after one year?

What has changed in your daily business since the take-over? How do your customers benefit from this new cooperation?

Ian Raymant: For Pultrex, it is great to have the extra support from KraussMaffei with regard to the pre-sales, sales and after-sales activities. There are more people available to visit customers and describe the Pultrex approach. We now have that improved network, which helps us grab those untapped markets and provide that extra support that the market badly needs.

Philipp Zimmermann: I think the main factor is that there is real synergy: Pultrex has that excellent know-how of 40 years and 600 machines in the market, and the colleagues here are really, really good. Now with the global KraussMaffei sales organisation working out of Europe, China, the US, or South America, we are getting enquiries Pultrex would never have before.

After we made the acquisition, there was immediate teamwork and positive exchanges between Munich and Manningtree, and now we are working as a team together on a daily basis. We discuss questions as to how profiles can be made, how machinery can be set up, and also think about the future, and what new kind of developments we can make.

What are the major benefits of pultrusion technology?

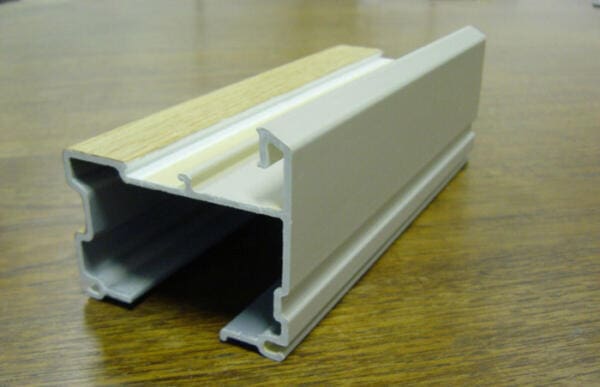

IR: We offer 40 years of experience of the thermoset open bath technology, and KraussMaffei has developed the innovative closed injection box iBox, where you can process faster matrix systems like polyurethane. Production speed is one of the most important issues for developing applications that have yet to be considered for pultrusion.

PZ: You can see that with rebar applications. Currently, in the market, there is a production speed of approximately 2m/minute. After two or three years of development, we have now achieved 10m/minute, and this is opening up new business cases for construction companies and for pultrusion companies because we can really start to fight against steel.

We want to go to 12m/minute, which is our own target. Also with polyurethane and maybe thermoplastic pultrusion in the future, this will give us even more opportunities in the overall pultrusion market.

“Pultrusion is the most efficient way to make a composite product.”

Philipp Zimmermann

In which market applications do you see the greatest potentials?

IR: We have evidence of increased interest in infrastructure, with products such as articles like lighting poles and obviously rebars, which features high in our common development programme.

Pultruded profiles have a lot of advantages: They are lightweight, non-conductive, radio-wave-permeable, so they can be used in transmission applications, and they have an extremely high strength-to-weight ratio. Plus of course, they do not corrode.

PZ: When you read about the kind of markets for composite applications, pultrusion has an expectation of significant growth over the next years, because everywhere where there is a profile inside, you can immediately consider pultrusion. As Ian explained, construction has real potential because there are a lot of different profiles.

For me, pultrusion is the most efficient way to make a composite product. You have rovings inside, which is a standard product you can buy from fibre makers, you have the resin, and then you have a really low amount of money you need to invest if you compare it with other technologies. In addition, you can produce continuously 24h a day. For customers, this can be a money-printing machine.

We at KraussMaffei have a lot of experience for instance, in Resin Transfer Molding (RTM) or in FibreForm which are all composite technologies. With pultrusion, the financial entrance barrier is much lower than with all the other composite technologies we had before.

What do you think will be the most important topics in the future?

IR: With polyurethane, we are already entering new markets, and we both think that with pultrusion combined with thermoplastics, this could create even more potential. That is why we are working in this direction.

Thermoplastics are obviously featuring highly on the eco side of engineering. Thermoplastic profiles are recyclable, can be welded and they can be reformed, rendering them able to be reshaped at a later date. With regard to rebars, you can just make one length of rebar, put it on a lorry, take the lorry load to site, and then form it to size. We are also looking at braiding technology for strengthening pipes.

A project we are involved in at the moment is aerospace, and we will be able to take that knowledge into the automotive sector for high-temperature, high-pressure fluid transmission.

PZ: When you work on increasing the production speed in the composite business, you cannot do this alone as a machine manufacturer, you need to have the right partners. With the new iPul Rebar line it was Evonic.

They supported us with raw materials, made adjustments, provided new resin for our testing. That way we were able to make inventions like a pretty fast winder for getting fibres around the bar. The heating and cooling were also quite challenging because you can imagine if you are running at that production speed, you need to get the complete bar very quickly solid.

So the new iPul Rebar line was the first common development between Pultrex and KraussMaffei?

PZ: Yes, and it really was a teamwork project. In the last eight weeks, we were working very much together with one of the guys, Steve Stiff, giving us information and his knowledge to finish the machinery itself. The team was coming together, exchanging information, and then we finally made the last steps so beautifully.

“We are experts in both technologies open bath and iBox injection, and together we can find the best solution for our customers – that’s the beauty of our alliance.”

Ian Raymant

Do you have further groundbreaking projects at the moment?

PZ: We are currently running a big development in pultrusion with a customer, where we have an iBox and a tool which is currently the biggest one I have ever seen so far in pultrusion. The profile is 12 metres long and has a diameter of 250 millimetres. In the near future, a diameter of even 350 mm is planned. It has several hundreds of rovings fitted inside and giving stiffness.

In another project, we have just sold a machine to a train manufacturer, where we make a 30-metre profile out of carbon. This is a complete roof for an underground train made by pultrusion. The customer wants to test this technology because it’s giving them the most efficient way of producing a composite profile.

You mentioned at the beginning that Pultrex uses the open bath technology and KraussMaffei invented the iBox injection box. If I want to start with pultrusion, what would you recommend?

IR: It all depends on the project. That’s the beauty of the alliance between Pultrex and KraussMaffei. Between us, we are experts in both technologies and can find the best way for customers to start with pultrusion and assist with introducing the most efficient way for profile production.

This interview was performed by Petra Rehmet, for ahead by KraussMaffei. For more company news, case studies and commentaries, visit KraussMaffei ahead.

KraussMaffei

+44 (0) 1925 644100

Website

Email