Fontijne Presses Blog // Are You Using the Right Testing Methods for Recycled Thermoplastics?

|

Getting your Trinity Audio player ready...

|

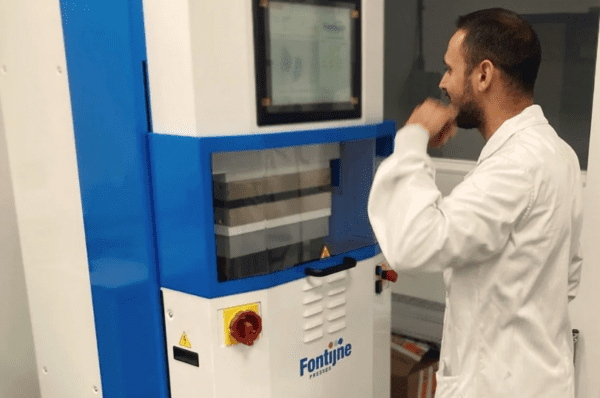

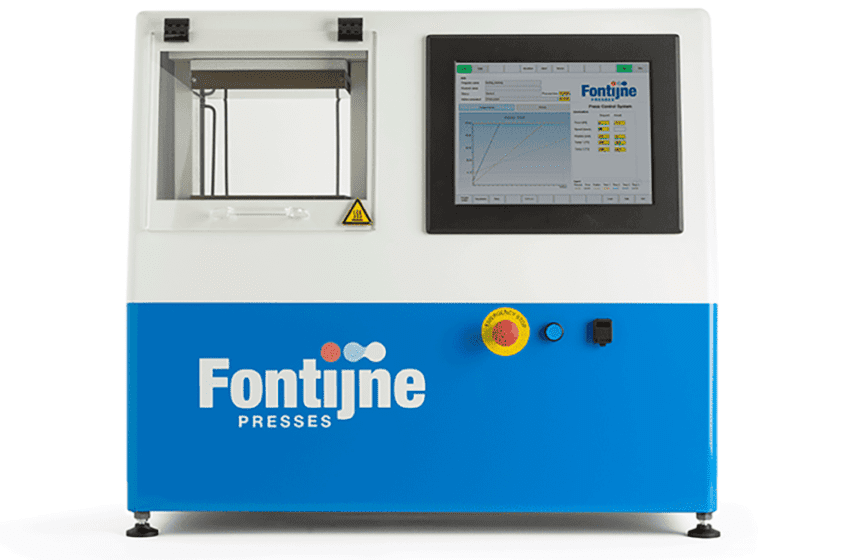

Achieving consistent quality across batches is crucial for the effective use of recycled thermoplastics, and laboratory presses can play a vital role in this process. By employing careful raw material selection, advanced technological expertise, and thorough process and quality monitoring, batch consistency comparable to virgin materials can be attained. In this blog, Fontijne Presses explores how laboratory platen presses can enhance the quality and consistency of recycled thermoplastics, providing reliable solutions for material testing and analysis to support effective recycling practices.

Laboratory platen presses are particularly useful in the realm of process and quality monitoring, as compression moulding provides a reliable method for producing test specimens and sheets that are homogeneous and isotropic, suitable for machining or stamping. Incorporating a few straightforward tests into your production workflow can significantly advance the professionalisation of your quality system:

Melt Flow Index (MFI) is a measure of how easily a thermoplastic polymer flows in its molten state, and is frequently used for polyolefins. When testing recycled PE and PP flakes, it has been observed that pressing the flakes into a sheet before cutting them into pieces for MFI measurements significantly reduces the standard deviation of the results. This leads to more consistent and dependable figures, ultimately saving time and money by reducing the need for repeated measurements.

Fourier-Transform Infrared Spectroscopy (FTIR) is used to identify different polymers and impurities in recycled thermoplastics by analysing their distinct infrared spectra. Depending on the test method, small sheets with a thickness between 50–120 µm are required, which can be easily produced with high quality using a laboratory platen press.

Density (ρ = m/V) measures the mass per unit volume of a material. To obtain an appropriate specimen, a sheet can be pressed from granules in a manner that minimises the entrapment of air bubbles. Since the density depends on the polymer’s crystalline structure, and the cooling rate during the crystallisation stage greatly influences the properties of (semi)-crystalline thermoplastics, it is crucial to maintain precise control over the cooling rate during this stage.

Visual detection is used to determine whether impurities, such as crosslinked PE, silicones, or metals, are present in the feedstock. It is also used to assess the level of contamination in the material after extrusion or granulation, allowing for optimisation of the mesh filter size.

A laboratory platen press is a flexible and user-friendly way to prepare a sheet or shim that can be used for visual detection. If applicable, the pressed shim can be heated and blown to simulate the actual film blowing process.

End of Waste (EoW) refers to the point at which a waste material meets the necessary criteria to no longer be classified as waste, but instead becomes a resource for new production processes. Recyclers must analyse the recycled material and demonstrate compliance with relevant product legislation, such as REACH, RoHS, or POP. They can follow the PRE-1000-2 standard developed by Plastics Recyclers Europe (PRE). X-Ray Fluorescence (XRF) is often used for initial screening through the PRE tool, and a cost-effective method for sample preparation is to use a laboratory press to form granules into a small plate.

The EuCertPlast certification (also available to UK companies) provides recyclers with the ability to assure suppliers and customers that the post-consumer plastics processed at their facility are handled in accordance with best practices and with environmental responsibility.

Intelicare are exclusive partners for Fontijne Presses in the UK and Ireland. Whether you are looking to batch test, start a new venture, or to upgrade your current equipment, contact presses@intelicare.co.uk or call 07815921951 to start the conversation.

Read more news from Intelicare here.

Intelicare

+44 (0)1777 248777

Website

Email